Is recycled plastics in food packaging possible?

Previously, we’ve talked about recycled plastics in films in our #RecycledPlasticsSeries and closing the loop in packaging context extensively.

In this article, we want to explore the innovation possibilities in the food packaging industry to join in the sustainability cause.

Innovation With Purpose

We believe innovation is essential for businesses to continue to thrive in this competitive market.

“However, innovation for the sake of innovation doesn’t always work.” – David Ang.

As such, Thong Guan’s innovation mission always revolves around three major areas

- performance and quality consistency,

- load stability and safety, and

- sustainability.

So today, we want to touch on possibilities for food packaging industry players and stakeholders to innovate for a more sustainable tomorrow—a challenging endeavour we should all join hands and strive for.

The demanding safety requirements on food contact materials have made adding recycled materials in food packaging challenging for packaging producers.

Fortunately, that does not mean it’s not possible.

Including recycled plastics in all types of packaging is ideal for the industry to promote sustainability.

The move into sustainability measures is only logical as packaging is inevitable for today’s global consumer demand.

The next best thing is to reuse the plastics that have been discarded—evidentially to close the circular loop, preserving not just the environment but also sustaining businesses.

So, what is possible for industry players to also embark on recycling for the food and beverage packaging industry?

The Global Food Packaging Market

The global food packaging market today is at a whopping USD 338.34 billion.

We expect it to grow to USD 478.18 billion in 2028 at a CAGR of 5.1% from 2021 through 2028.

The Covid-19 pandemic has brought on a shockingly positive demand for such products.

Undeniably, it has been increasing pre-pandemic as well. That has led to the rise of diversified packaging materials and solutions from innovative technologies.

Unfortunately, the process has always been linear, from raw materials to production and eventually disposal. And sadly, they all ended up as municipal waste where their end of life is in landfills or ocean spillover.

Why can’t we use recycled materials in food packaging?

We can. However, the application is limited with stringent legislation approved threshold.

As the global sustainability efforts rise, many policymakers are slowly accepting recycled materials in packaging that will contact food and beverages—with strict limitations.

It is still a controversial topic filled with concerns and heated debates.

Undeniably, it is crucial to protect our health and safety.

So some of the regulations around the world allowing recycled plastics in F&B application may include,

- Must come from end-of-life packaging that contained food, NOT packaging that contained cosmetics, for instance.

- Must be decontaminated through an approved process

Still, many rules and regulations worldwide are still prohibiting recycled materials in products that will come in contact with foods and drinks.

Must we risk the environment for our health and safety?

Why must we choose one over the other? As environmental damage also affects our health and safety.

So can technological advancement and innovation be the answer to our health, safety and sustainability concurrently?

Design for Recycling

Recycled materials as a mid-layer in a three-layered structure

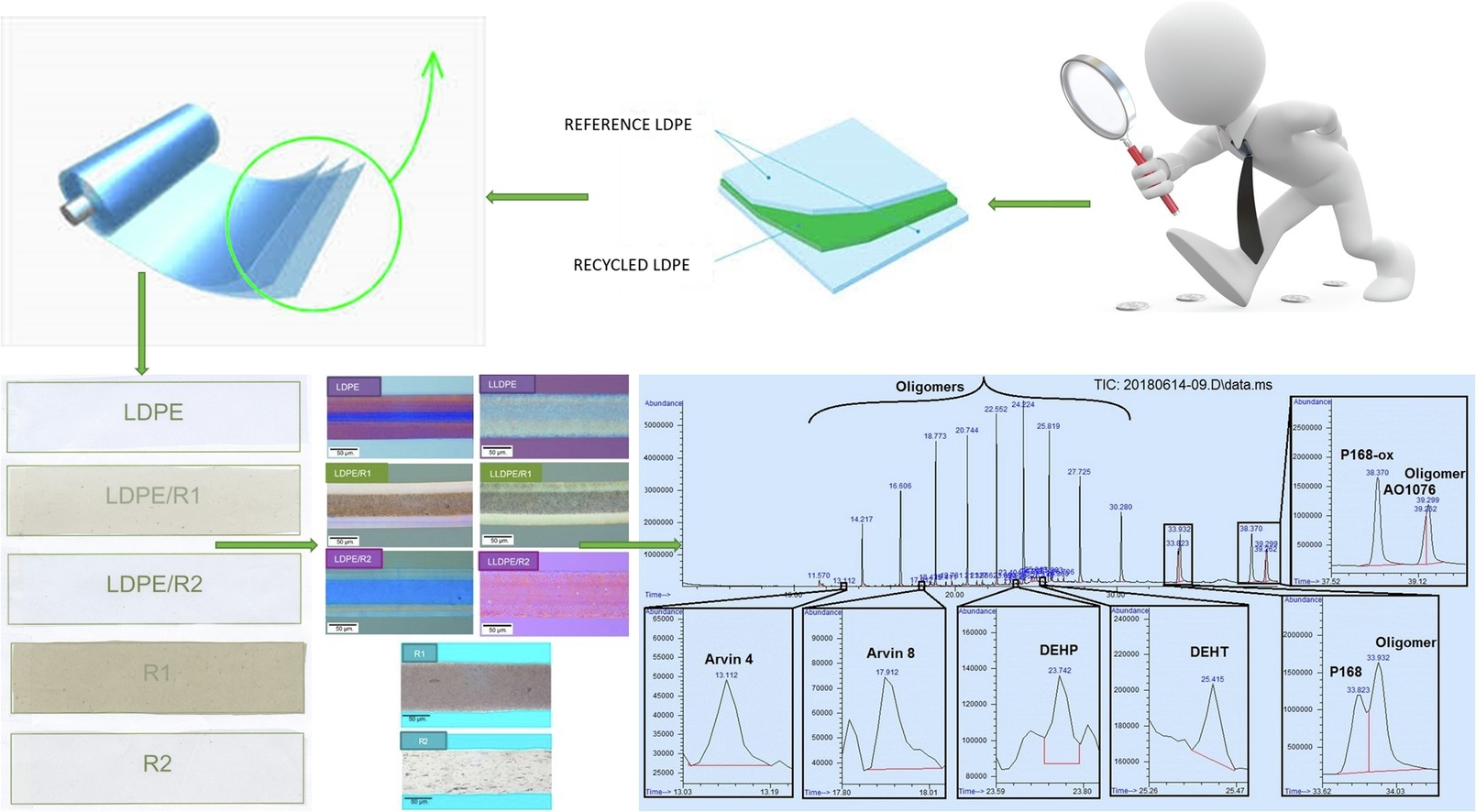

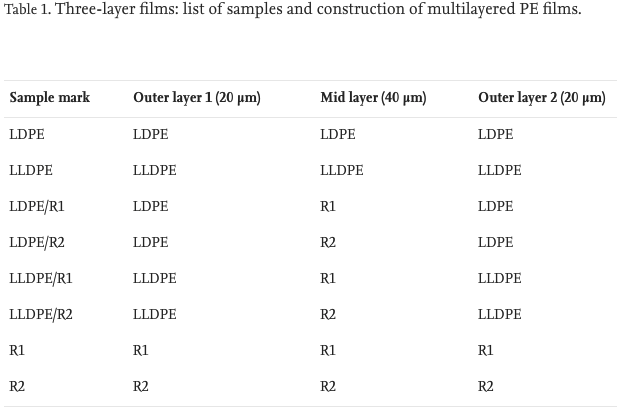

A study from 2019 through 2020 investigated the possibilities of designing food packaging for recycling.

The following is a summary of the test on recycled materials in multilayered PE films. Note that we did not include the detected chemical compounds in the plastics found in the study. For more details, you may check out the study here.

About the test

- Potential use of recycled flexible polyethene in food packaging

- Screening test: migration analysis with 95% ethanol at 20°C, 40°C and 60°C

- Migration values were below the overall and specific migration limit (OML & SML, respectively)

- The addition of recycled mid-layer influenced visual optical properties

- Overall migration test was determined according to European standard method EN 1186

- Specific migration analysis was carried out according to European Standard EN 13130

- Both OML & SML is defined in Commission Regulation EC 10/2011 as the maximum permitted amount of a given substance released from a material or article into food or food simulants (Commission, 2011)

- The virgin LDPE (density 923 kg/m3) is developed for packaging film applications, like shrink film (lamination films) and carrier-bag film and pouches (food packaging). It contains no additives. The product is suitable for recycling.

- The virgin LLDPE (density 931 kg/m3) is developed for packaging film application. It contains additives and is suitable for recycling.

- Recycled material 1 (R1) is commercially available recycled material from PCW (density 930 kg/m3). According to the producer, it is produced using a special blend of LDPE and LLDPE post-consumer recycled plastic; well suited for blown film processing and recommended for applications like carrier bags and other flexible packaging applications.

- Recycled materials 2 (R2) is a commercially available custom-made blend of PCW and post-industrial polyethene (density 927 kg/m3).

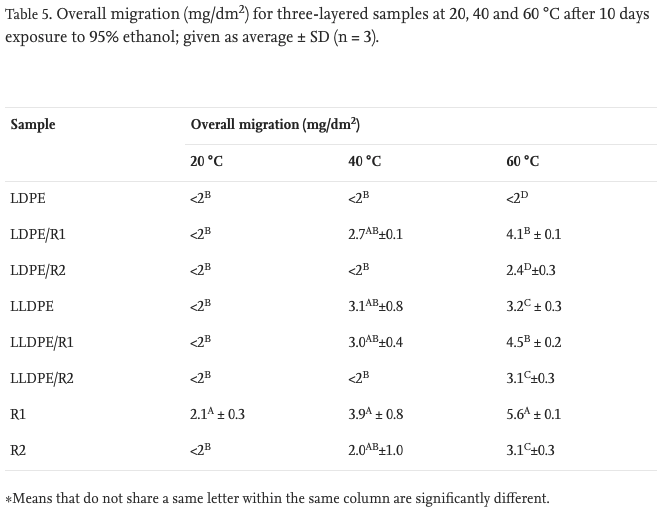

The Migration Test Results

OML Standard

Overall migration values for all temperatures were from <2 mg/dm2 at lowest and 5.6 ± 0.1 mg/dm2 at the highest temperature, thus well below the overall migration limit (OML) of 10 mg/dm2.

SML Standard

The following is a list of approved substances for food contact materials (FCM) and additives commonly used in plastic materials in SM analysis.

- P168

- P168-ox

- AO1076

- AO1010

- DEHP

- DEHT

- Oligomers

- Arvin 4

- Arvin 8

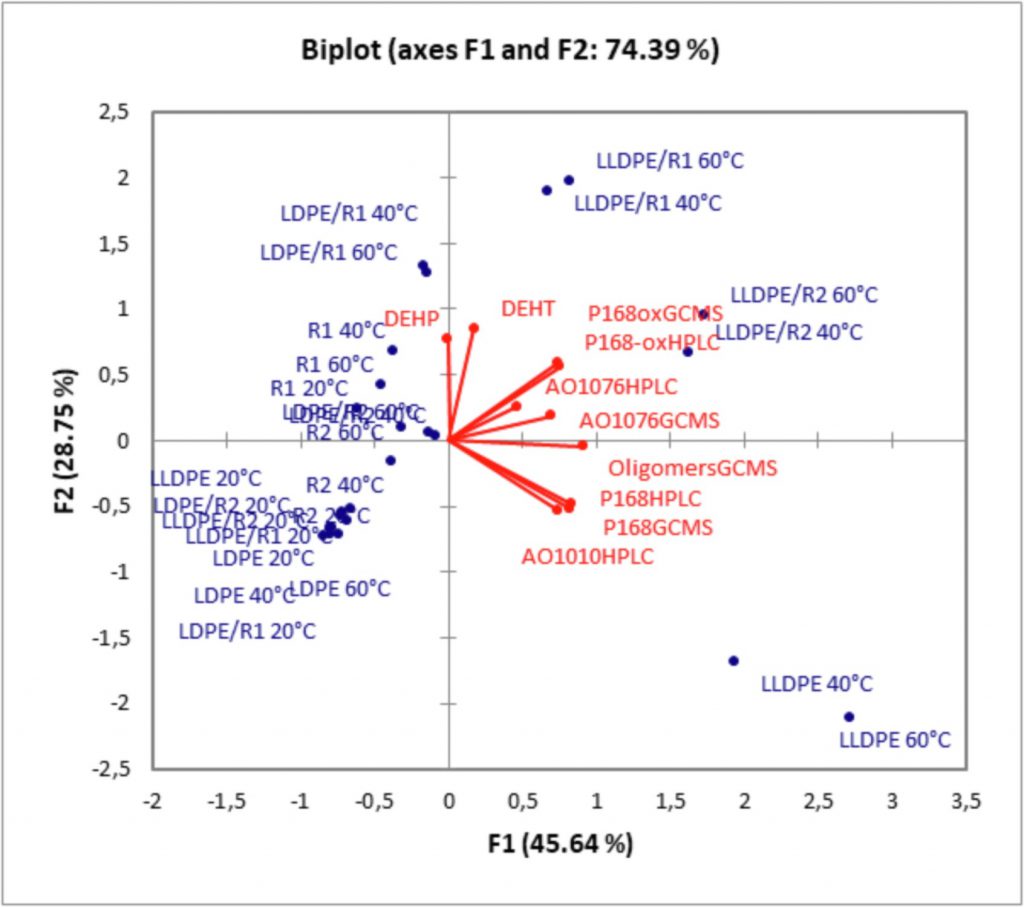

The targeted chemical compounds are detected and quantified using High-Performance Liquid Chromatography (HPLC), and Gas Chromatography-Mass Spectrometry (GCMS) methods in this study and results are populated as shown below.

The highest migration values from overall and specific migration were observed in LLDPE/R1 materials, while the lowest was for LDPE/R2 materials. Hence this was the best solution for the use of recycled mid-layer. However, both OM and SM values were below the limits stated in the legislation, pointing out their possible use as food contact materials.

The Results on Optical Properties

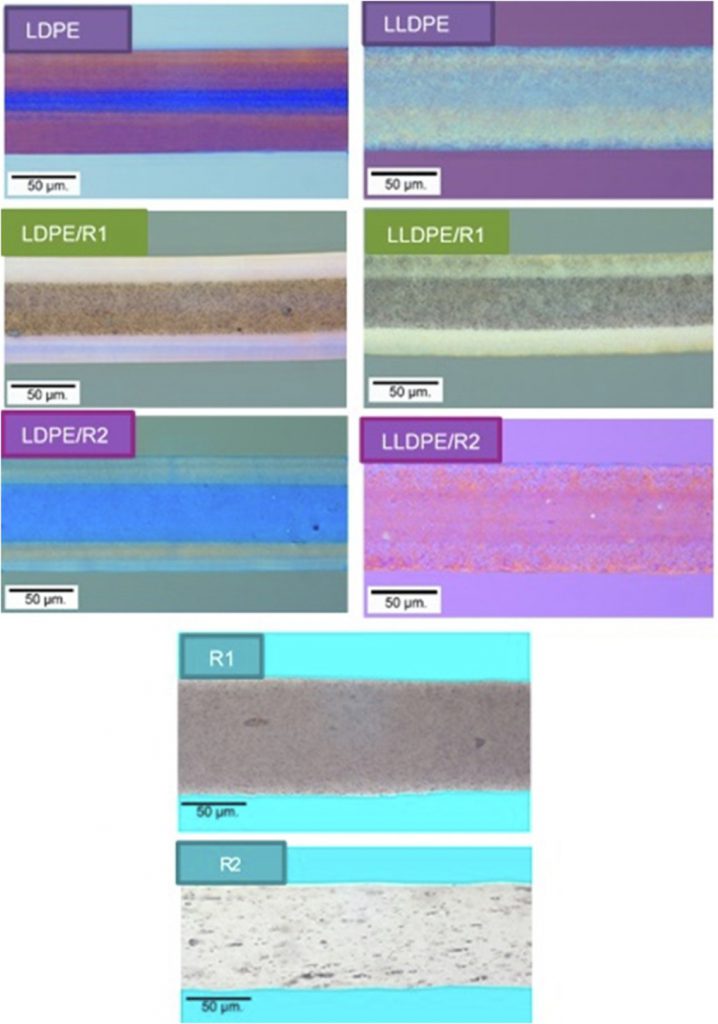

The following shows the optical measurements and visual tests to illustrate the influence of recycled mid-layer on the appearance of 3-layered structures.

Films containing recycled mid-layer (LDPE/R1, LLDPE/RI, LDPE/R2, LLDP/R2) have a certain amount of impurities (visible as particles and gels in microscopy cross-section) compared to virgin samples (LDPE, LLDPE).

With the outer layers of virgin materials of 20 µm and transparent, we can see that R1 causes significant colour changes compared to R2 with less visible influence on the visual colour and cross-section.

The following shows the appearance of LDPE layered films.

The following shows the appearance of LLDPE layered films.

Particles and gels visible on the microscopy cross-section are causing these changes, influencing visual effects and material properties.

The material’s appearance changes may be a drawback to some brand owners, though it shouldn’t.

However, it may limit the applications of recycled plastic packaging.

The Results

The temperature test will tell us whether the recycled materials will migrate from the inner layer into the outer layer. And whether the chemical compounds in plastics are within OML and SML defined in rules and legislation.

Temperature does affect the migration risks. Positively, they are lower than the specified limit. It’s what most brand owners are worried about.

Also, in the F&B market, appearance takes precedence as ill-looking foods are not appealing.

Appearance-wise, as this matters highly in the food industry, only slight differences in appearance. Supposedly, good news for opting for a greener route for the future.

What the study means to us

So why is this study important to us?

It’s a hope to us that recycled plastics in food packaging is looking more hopeful for us to strive for a better future for our next generation.

With the right formula, we can take a better route towards sustainability than pure virgin plastics in food packaging.

This research presents a valuable study on migration from recycled flexible PE films and recycled materials in food packaging applications. The use of virgin materials as outer layers in combination with commercially available recycled material can increase the use of recycled materials in packaging and reduce the total amount of flexible plastic solid waste.

It is a relatively positive test result to give food industry brand owners a better understanding of the risk to assess the potential benefits of recycled materials in food packaging.

As for plastic packaging producers, this marks a beginning for us to venture into the realm of possibilities—a future of sustainability and hope.

Conclusion

Policies and regulations are put in place to protect us.

However, that does not mean policymakers and regulators should continue to hold on to non-sustainable measures.

As the world progresses towards technological innovation and sustainability, we should also update policies and regulations to embrace change. But that doesn’t mean we should forsake our health and safety as well.

Ideally, technological innovation and advancement could answer for better health and safety, making regulation even stricter to protect ourselves.

In other words, we should do better with technological inventions to surpass possibilities.

Perhaps, one day, we can have fully recycled materials in food packaging that enable a circular economy and are safe for both humans and the environment.

The possibilities are there, bringing ample opportunities.

Now, it’s up to us as industry stakeholders—policymakers, manufacturers, brand owners, suppliers, and more—to make it possible together.

Thong Guan continues to champion green efforts through our #LiveGreen initiatives. Let us all move forward for a better tomorrow together.

If you are interested in any of our #LiveGreen initiatives or have great green innovation to share, please do not hesitate to contact us at info@thongguan.com.