Health & Safety

Our Sustainability Indicator

Health & Safety @ Workplace

The establishment of the Occupational Safety and Health Administration (OSHA) in 1970 reflected the recognition that safety in the workplace is a basic expectation for all employees. Originally addressing concerns in industry and hazards associated with mechanical injury, today, the field of occupational health and safety has expanded to almost every workplace environment.

Integrated Quality, Safety, Health & Environment Policy

The Management of THONG GUAN have established this Integrated Quality, Safety, Health & Environmental (QSHE) Policy to be consistent to the purpose and context of our organization. THONG GUAN, a manufacturer of printed and non-printed stretch films, plastic bags and sheets, shall be committed to comply with the legal and other requirements that the company subscribes and to continual improvement pertaining to quality, safety, health and environmental through:

- Training – create awareness on quality, safety, health and environment

- Protect and Green the Environment.

- Prevent pollution, injury and ill health.

- Programs for improvement on safety, health and environmental.

- Improvement on Quality, exceeding customer’s requirements towards Trust and Established Partnership

This policy shall provide a framework for establishing and reviewing the objectives. THONG GUAN shall be responsible to ensure the policy is communicated to all employees, vendors and available to the public and interested parties upon request.

TG’s OHS Management System

The purpose of Thong Guan’s Occupational Health and Safety (OHS) management is to promote a comfortable and safe workplace based on the most advanced practices. Its aim is to contribute to the welfare of the Group’s employees and the development of Thong Guan’s business. In addition, the Group has established in its regulations that it will give careful consideration to the health and safety of the employees and sub-contractors who work full-time in Thong Guan premises.

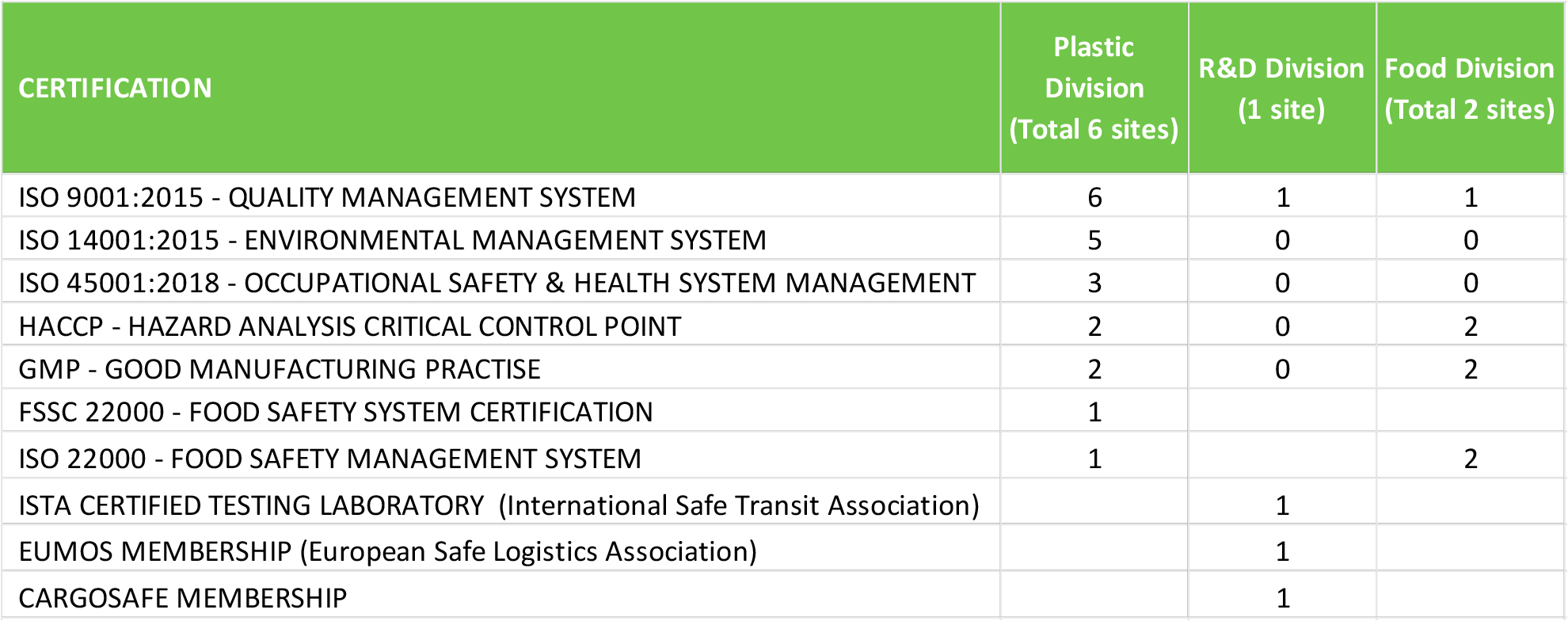

To maintain our occupational health, safety efforts, and to continuously improve them. Thong Guan has introduced an occupational health and safety management system its manufacturing sites. At various TG business sites, ISO certifications related to OSH are mandatory.

As at August 2022, certification obtained by TG companies relating to Health & safety include:

Employee well-being

Offering employees, a well-designed and comfortable work environment is integral to our commitment to investing in our workforce. This includes providing well-ventilated offices and noise pollution according to applicable regulations.

We appreciate that diverse roles require different working hours, routines and approaches. The production process, for example, involves shift and rotation work that offers less flexibility. Our site supervisors are empowered to discuss individual needs to balance work and rest and are expected to respond appropriately.

During the COVID-19 pandemic, many of our employees were given the option of working from home. We provided face masks to the employees. We conduct RTK Antigen testing on a biweekly basis according to requirements. We educate our employees on vaccination and provide transportation to vaccine center. Our employees are fully vaccinated by Oct 2021.

We also provide occupational health services, including medical surveillance tests and audiometry. We outsource this work to external providers to support employees’ health efforts.

Our Actions

Implementation of our OHS management system is our important routine at our workplace. Actions include-

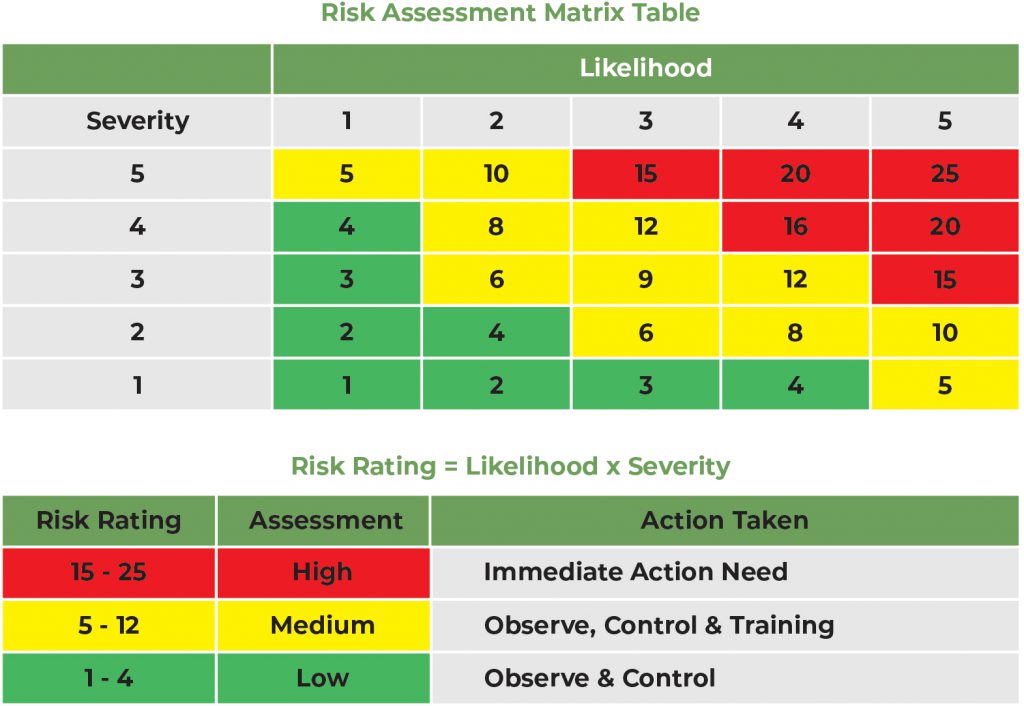

- Conduct at least once a year regular risk assessments of sites elements including mechanical equipment and harmful substances, this process aims to identify potential risks of workplace accidents or illnesses and to ensure to reduce these risks, according to their level of severity.

- When a workplace accident happens, Corrective actions and post mortem information is share through its corporate intranet. Experience sharing and actions plan can prevent recurrence of such accidents at other business sites.

- All business sites in Malaysia have a Health and Safety Committees, composed of employees and managers. The purpose of these Committees is to ensure continuous improvement on the OHS. This includes implementation of hazard prevention measures, investigation of root causes of occupational accidents, prevention measures for employees’ health issues as well as employee health maintenance and promotion measures.

- Thong Guan has established Occupational Health and Safety Councils with its contractors in order to prevent occupational accidents caused by contractors’ employees operating on our premises. These Councils serve to maintain open lines of communication among workers and to comprehensively manage health and safety issues.

- At our Headquarters, we have built a system for managing the status of occupational accidents arising at all TG subsidiary companies. Should a major occupational accident occur, this system allows reporting it within 24 hours, in addition to full year- round monitoring and sharing of case studies with all Group companies.

- At business sites where occupational accidents have occurred, Thong Guan investigates the root causes behind incidents and implements measures at all business sites to prevent the recurrence of similar accidents.

- All industrial accident cases have to investigate within one week and the suggested measurements have to implement within one month from the report issuing date.

- Our Health and safety officer and his team also participate in an annual Employee Personal Health and Occupational Health and Safety Forum and attend relevant seminars. Through learning to increase their knowledge and to put it into practice at each business site.

- All business sites’ Health & Safety Committee Chairman is the committee member of the Group Health & Safety Committee (GHSC) GHSC is Chaired by the Group Health & Safety Officer. The GHSC is directly reports to the Operations Group Executive Director who is a Board member. The Occupation Health & Safety matters is also discuss in the Enterprise Risk Management Committee, Audit Committee and also is a key area for internal audit by an external internal auditor.

Fact & Findings

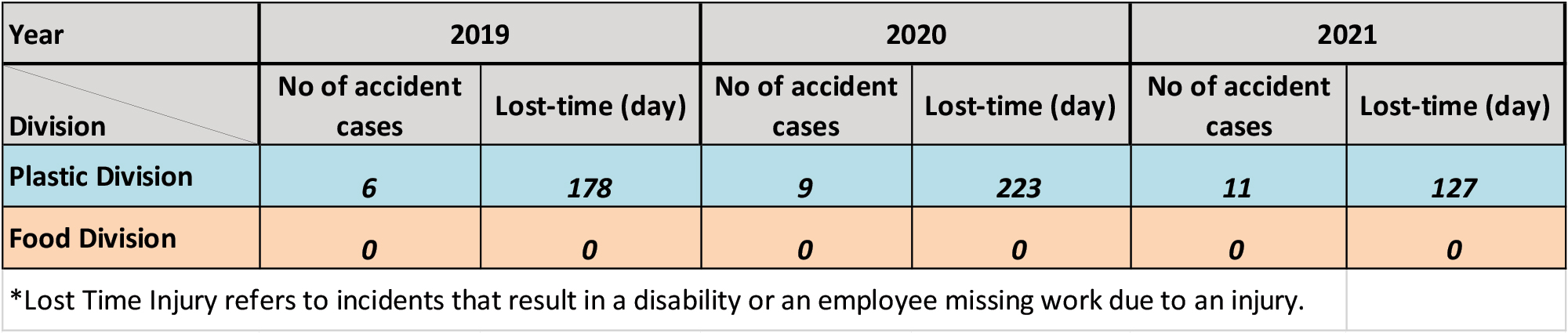

Industrial Accidents Records and Lost Time

It is the Group’s target to minimise the number of industrial accident and target to achieve by year 2023 to maximum 1 case yearly per business site for plastic division (total 7 cases) and total 1 case for food and beverage division.

Training Record related to Health and Safety

Year 2020 | Year 2021 | Year 2022 (8 months) | |

|---|---|---|---|

No of Headcount trained

| 195 | 87 | 459

|

Total Days

| 283 | 137

| 670

|

Total Hours

| 1981 | 959

| 4690 |

Average Hour per Headcount

| 7.0 | 11.02

| 10.22

|

The Group emphasis on its employees health and safety at work. During the period, the Group has conducted the below health and safety training and related program for its employees:

- Chemical Safety & Hazardous Waste Management

- Basic Fire Fighting

- Introduction to First Aid & CPR

- Certificate in Occupational Safety

- Safety, Health & Environmental Training

- Course For Certified Environmental Professional in Schedule Waste Management (CePSWaM)

- Schedule Waste Management Training Program

- Forklift Safe Handling Training

- Hearing & Conservation Training

- Safety, Health & Environmental Training

- Chemical Safety Management

- Bengkel Pembangunan Generik Pentaksiran Risiko (RA) bagi Sektor Pembuatan Plastik

- Technical Report Preparation Workshop for EiMAS CePSWaM Competency Certificate 2022

The above training is conducted by way of in-house training program and is trained by internal qualify trainer or external trainer. The group also send employees to participate in external training program conducted by HRDF approved training providers. All participants are requested to evaluate program effectiveness at the end of the training session. The participants also asked to indicate the usefulness of the program and the applicability of the course content into their working environment.

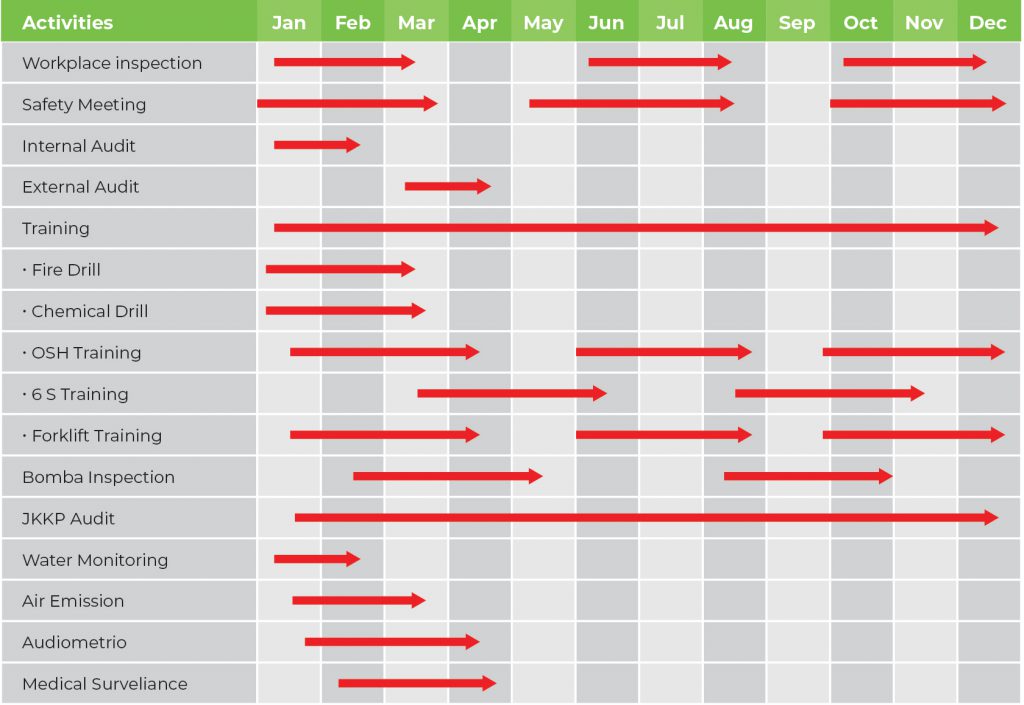

- TG’s yearly work plan related to OHS management system

ISO Milestone

Risk Assessment Matrix table