Now that we’ve talked about the differences between PCR & PIR, let’s talk about plastic mechanical properties. How do we achieve customers’ film requirements, particularly for recycled films? It takes to make high-quality films. As such, most importantly we look at data—the films mechanical properties and profiles.

As we obsess over the mechanical properties of the films we produce for our customers, we also focus on the intrinsic implications.

Undoubtedly, for less wastage, fewer damages and lowered overall costs that improve our customers’ bottom line.

Therefore, Thong Guan’s sustainability journey revolves not just on green innovation but also on achieving our customers’ film requirements.

How to achieve film requirements?

Clearly, achieving film requirements takes a lot of complex processes and approaches.

In a nutshell, here are the summary profiles we look at to ensure quality films.

Mechanical Properties of Cast Stretch Films

and the correlated characteristics

- Elongation (Stretchability): the measurement of ultimate stretching of the film until it breaks to measure its stretchability threshold

- Clinginess: a measurement vital to maintaining a tight wrap around your load

- Puncture: measures properties such as maximum force, breaking strength, and penetration distance.

- Tear propagation: the measurement of resistance (how long and how much it takes) to the expansion of a tear

Blown Film Profiles

- Thickness tolerance: We have a thickness profile control system to ensure our films meet the nominal thickness requirements by controlling the actuator.

- Width tolerances: A measurement control using an ultrasonic bubble sensor (USB) and internal bubble cooling (IBC) to ensure it is within ±5 mm.

- Mechanical properties: Fully customisable based on our process and materials to meet the customer’s requirements.

- Extruder back pressure: Well-controlled system to ensure the pressure is within tolerance for consistency.

- Optical properties/film planarity/free of wrinkles/size & roll consistency: A combination of a control system and processing to ensure repeatability of the consistency to give our customers the perfect thickness, properties, and quality consistencies.

Impact of recycled resins in our films’ mechanical properties and profiles

Without a doubt, recycled plastics are increasingly popular for sustainable reasons.

Moreover, besides the devastating worldwide plastic pollution, we’ll also be depleting our dwindling natural resources of petroleum.

As we know, plastic is an inevitable creation.

So, the good news: plastic is highly recyclable. The bad news: plastic waste management is the problem.

Hence, we look at recycling plastics, effective collaborations, and green innovations to improve our game towards a more sustainable world.

However, one major concern remains: Will recycled resins produce films with the same quality functions as virgin resins?

In this article, we want to address this concern with our very own in-house testing.

No doubt, the simple answer is yes—recycled resins produce films with inferior properties to virgin resins.

Fortunately, as our sustainability efforts increase over recent years, Thong Guan has invested heavily in exploring viable green innovations—from R&D to testing capacity, compositions, and of course, the mechanical properties of our films.

Mechanical properties are the behaviour of plastics when varied forces are applied. We believe by focusing on the behaviour, we can effectively compensate the inferiority.

Flexible packaging is designed to withstand stress to protect your goods throughout the supply chain—from production to consumers. That is why the mechanical properties of the polymers are vital in playing their role—regardless of the materials incorporated.

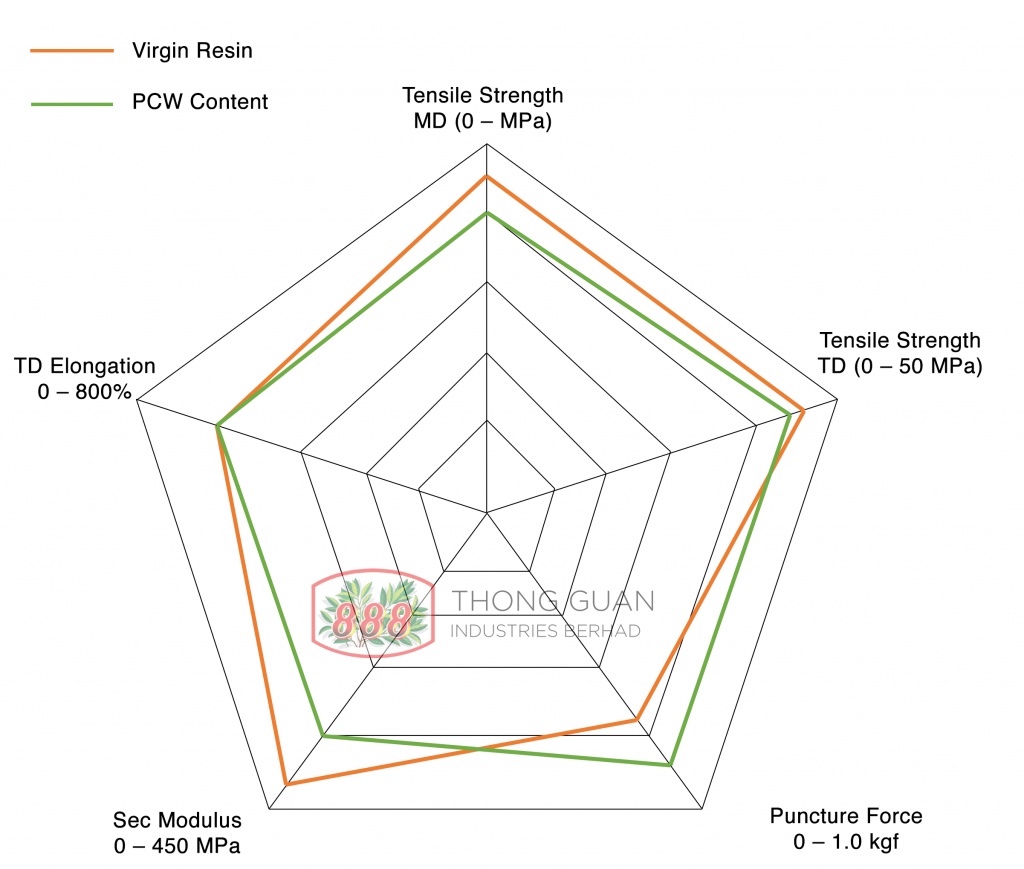

The stress test on blown films

Here’s the output of our blown film stress test on virgin resins versus PCW recycled resins.

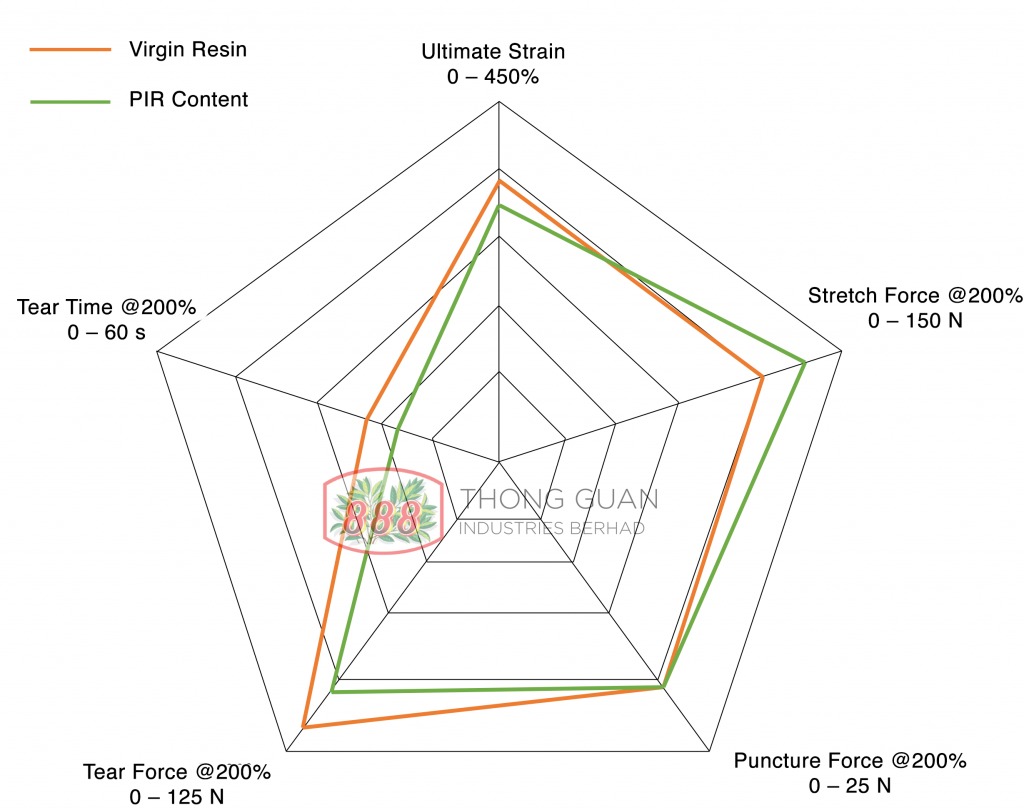

The stress test on cast stretch films

On cast films, here’s a radar chart that shows our in-house quality test of a stretch film between virgin resins and PIR recycled resins.

On the spectrum of 200% working zone, this film shows good data on the stress-strain test.

Stay tuned to our announcement of our very first recycled machine film.

Why mechanical properties are important

The result shows that we can integrate recycled materials in our films while retaining the desired film quality with the proper focus, design and formulation. Once again, the key factor to film quality is a deep understanding of plastic mechanical properties and profiles and the adjustment necessary to achieve the desired outcome.

However, we all know,

“…the best film with the best wrapper in the market does not make a perfect application.”

It is important to note that all films require optimum wrapper settings and best-fit application to achieve the containment force you are looking for.

It is best to talk to our sales representative to get the best fit for your application needs. You can email us at info@thongguan.com.

This article is part of the #RecycledPlasticsSeries. You may access all the articles under this series by searching for #RecycledPlasticsSeries.