Sustainability

SUSTAINABILITY STATEMENT

Thong Guan Industries Berhad’s (hereinafter referred to as “Thong Guan”, “the Group”, “us”, “our” or “we”) is proud to present our Sustainability Statement for the financial year from 1 January 2019 to 31 December 2019 (“FY2019”). This section presented the progress we incorporated sustainability measurements into our business operations and activities. We understand that the embrace of sustainability is a consistent and long journey. We will focus on the concerns of all stakeholders’ economic interest, environment interest and social interest to ensure sustainability governance is in place.

Introduction

In this fast pace era of business globalisation, Thong Guan business has been continuously evolving to strive for sustainable growth. Over the years in business operations, we have established a well-diversified plastics packaging products and food and beverage (“F&B”) businesses with global product presence in over 70 countries. As we continue our strides of growth, we are very cautious of our impact on the economic, social and environmental matters. Therefore, it is pertinent to understand the matters that affect the Group’s sustainability and to ensure that we identify and manage it accordingly.

Reporting Scope

Thong Guan is committed to the provisions of Main Market Listing Requirements of Bursa Malaysia on reviewing, updating and reporting our sustainability performance on an annual basis. The reporting during the year in review covers the Group’s operations in Malaysia. Our reporting has been prepared in accordance with the guidelines set out in the Main Market Listing Requirements in relation to the Sustainability Statement in Annual Report of Listed Issuers (Guidelines) issued by Bursa Malaysia Securities Berhad.

We strive to do our utmost to strike a meaningful balance between our economic aspirations and our social and environmental obligations. This Sustainability Report details our continuous efforts to ensure that as we pursue growth in profits and expansion of our operations, we remain vigilant of the economic, social and environmental impact of our actions.

Sustainability Governance

Our sustainability framework is led from the top and the responsibilities played by each level of our organisation.

Executive Directors

- Review the Group’s sustainability matters and ensure business strategy considers

- Provide advice and direction of sustainability in the Group when

- Approves sustainability strategies and

Management

- Responsible for assessing and identifying material sustainability

- Develop sustainability strategy and recommendation and regular revision is in

- Undertake actions necessary to address sustainability

- Oversees operating divisions in ensuring robustness of system of sustainability

Operating Divisions

- Supports strategy implementation develop by the management to ensure sustainability objective is

- Ensures sustainability processes and controls are in place within its departments/functions.

- To review and feedback on all measurements for

Stakeholder Engagement

Stakeholder engagement is a key element to ensure businesses are continue relevant and value added. The table below show the engagement activities that have been carried out during financial year 2019.

Stakeholders | Areas of Interest | Method and Frequency |

|---|---|---|

Investors / Shareholders | • Profitability • Dividend • Business directions | • Quarterly financial result • Annual General Meeting • Company website • Annual Reports • Press release |

Customers, Suppliers and Business Partners | • Product and service quality • Timely delivery & consistency in supply • Credit worthiness • Value added products | • Customer satisfaction survey / supplier evaluation • Customer service and communication • Trade fairs and frequent site visits |

Employees | • Career & learning path • Employee welfare and benefits • Health and safety in work place | • Communications through counselling and memo circulation • Continuous improvement of workplace • Bi-annually performance appraisal • Trainings and workshops • Employee events including outing and get together gathering |

Regulators / Government / Authorities

| • Compliance with laws and regulations | • Compliance and certification exercises including site visits and audits by authorities /certification body

|

Local Community | • Corporate social responsibility | • Educational site visits • Sponsoring sports and educational programmes • Community outreach programmes |

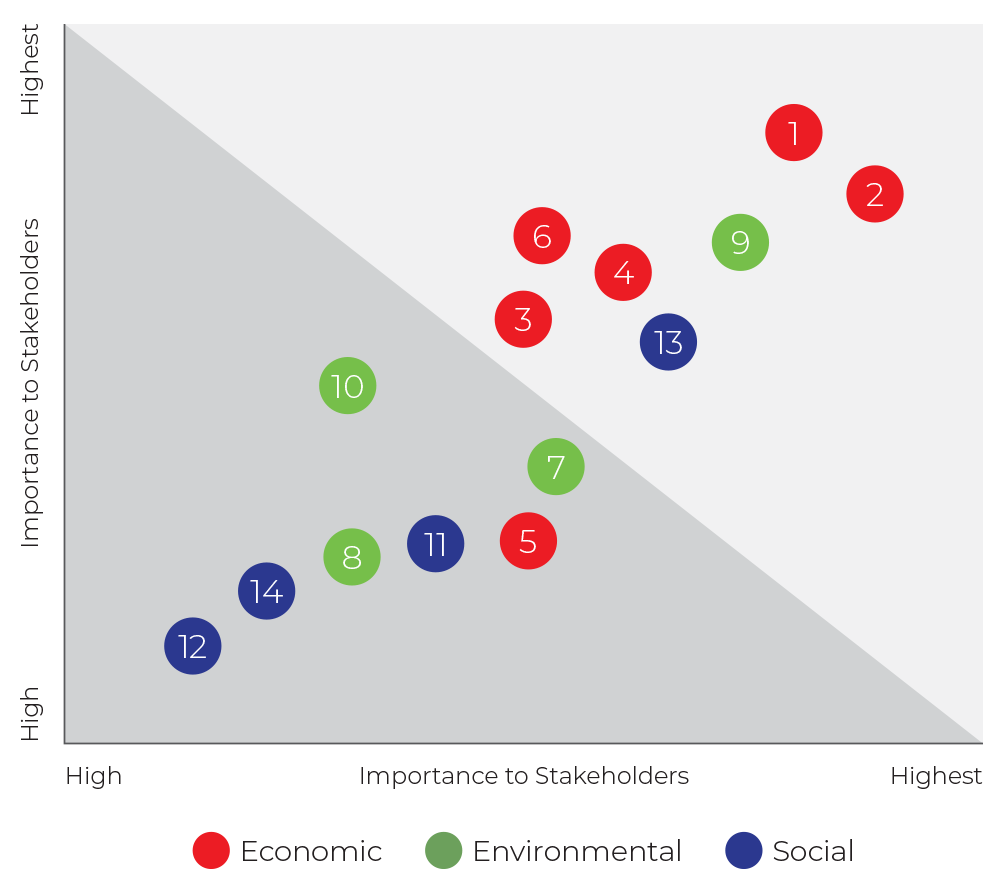

Materiality Assessment

Materiality assessment is conducted to identify and prioritise the economic, environment and social topics that may potentially impact Thong Guan’s business and its stakeholders. The steps involved in the materiality assessment are summarised as below:

Step 1

Identify sustainability matters that are material or important to Thong Guan business operations and its stakeholders. A total of 14 material sustainability matters were identified.

Step 2

The identified material sustainability matters were ranked on a scale of 1 to 9 according to its importance to stakeholders.

Step 3

The identified material sustainability matters were ranked on a scale of 1 to 9 according to its importance to Thong Guan business operations.

Based on the materiality assessment, the identified 14 material sustainability matters are those which are relevant to our business operations and stakeholders. These matters were then plotted into a matrix for better visualisation of the critical material sustainability matters.

ECONOMIC

1. Anti-Corruption

2. Economic Performance

3. Market Presence

4. Product Quality & Assurance

5. Procurement & Supply Chain Management

6. Product Innovation

ENVIRONMENTAL

7. Environmental Compliance

8. Materials Consumption

9. Waste Management

10. Energy

SOCIAL

11. Diversity & Equal Oppotunity

12. Employee Turnover & Retention

13. Occupational Health & Safety

14. Local Communities

The identified material sustainability matters are categorised as the highest priority (in blue shades) to our business operations and stakeholders, while those that are located in the light blue shades of the matrix are of high priority. We note that the 14 material sustainability matters represent the 3 pillars of sustainability where each matter will be relevant to the interest and concern of different stakeholders.

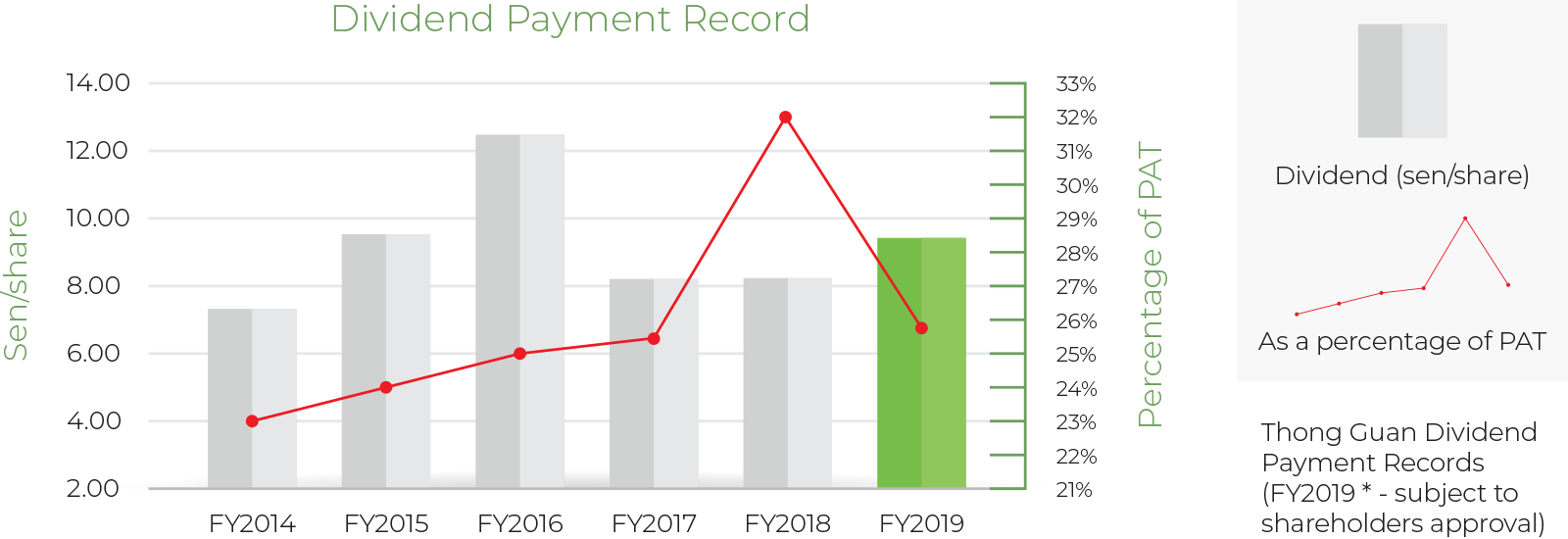

Sustainability Matters of Economic Interest

Thong Guan is striving to achieve a sustainable financial performance and fulfil our obligation to our shareholders. As a listed company, we generate returns to our shareholders in two ways: dividends and capital appreciation. We understand that this is highly dependent on the company’s financial performance. Hence, we are committed to upholding integrity to preserve shareholders’ interest and putting efforts to growth the business to achieve our double up mission.

We are also continuing our effort to maintain high standards of corporate ethics and strict compliance with laws and regulations in sustaining our business. The Board of Directors is guided by a Board Charter and Code of Ethics and has adopted a Sustainability/Environment, Social and Governance (ESG) policy, Whistleblowing policy and Corporate Disclosure Policy.

Sustainability Matters of Social Interest

Our efforts to develop sustainability in the Social aspect include both internal employees and surrounding communities.

Workforce

The Group is an equal opportunity employer that promotes inclusivity in the workplace. We provide an inclusive work culture that supports diverse talents who contribute positively to the growth and productivity in line with the Group’s vision and mission. Employees are always an asset to the Group, and we are committed to the welfare and wellbeing of our employees. We always provide our employees with a safe, secure and conducive working environment. We also putting in efforts on nurturing talent and provide opportunities for career advancement.

The Group complies with all employment regulations and guidelines set out by the Malaysian Government and relevant bodies:

- Established policies for the Group that supports no child labour, no forced labour, no discrimination and fair labour practices within the

- Established Whistleblowing Policy, No Gift Policy for the Group which provides an avenue and proper channel for stakeholders to voice legitimate This is the Group’s aspiration to conduct its business and operation with high integrity and transparency.

- We comply and respect the right to minimum wage for all our employees in Malaysia and China and comply with the requirements on paying overtime rates as well as working excessive

- We promote gender equality and staffs are promoted strictly based on merit without discriminating gender, age, race, or

- The Group has conducted internship program by recruited 27 students in Year

- The Group is currently employing 6 handicapped

Trainings

On the employee retention and talent development efforts, the Group has a plan to send its employees to attend internal and external training programmes to enhance and improve their knowledge. We understand knowledge improvement of the employees is an utmost important path in their career advancement and skill upgrading for job performance and productivity.

Training Programme Conducted for Year 2019

Internal - 47%

External - 53%

The Group is certified with OHSA 18001 Occupational Health and Safety standard. We place important on occupational health, safety and wellbeing of our employees. We ensure adequate insurance and hospitalisation coverage for all workforce and executives. Our employees are covered for Hospitalisation & surgical policy, personal Accident policy and group term life policy.

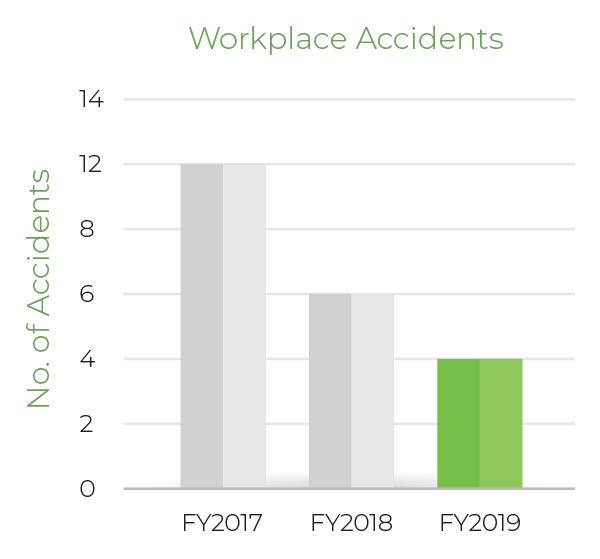

Occupational Safety & Health (OSH) activities

The safety and health of our employees, partners and local communities has always been a top priority. Any fatality is unacceptable. We are determined to enhance the safety culture across all of our operations to prevent the recurrence of such incidents. The Group has continuously conducted several OSH activities during the year and we have successfully reduced the workplace accident by 25% as compared to last year.

The list of Activities conducted in Year 2019

QMS

- ISO 9001:2015 QMS Standard Requirements & Awareness

- ISO 9001:2015 Internal Quality Auditor Training & Workshop

- Root Cause Fixing – Preventive and Corrective Actions

EMS

- ISO 14001:2015 EMS Standard Requirements & Awareness Training

- ISO 14001:2015 Internal Environmental Audit Training & Workshop

- Safe Chemical Handling and Spillage Control

- Safety, Health & Environmental Training

- Hearing Conservation, Noise Protection and OSH NADOPOD Reg.2004 Training

OHSA

- ISO 45001:2018 Internal Auditor Training & Workshop

- ISO 45001:2018 Transition & Awareness

- OHSA Management Roles & Responsibilities Training

- Occupational First Aid & CPR Training

- Forklift Safe Handling

- Basic Fire Fighting

As the staff safety is always our main concern, we have implemented proactive measures to prevent incidents and to minimise risks.

- Following the Health, Safety and Environment (HSE) rule and practice in

- Regularly check on safety equipment.

- Communicate people with potential risk in

- Wear appropriate Personal Protective

- Reporting all related incident to the safety and health officer and

- Reporting any near miss & unsafe condition to the safety and health officer and

- Directing people to safety training

In addition, rules and regulations have been enforced to ensure a safe working environment for our employees as well as visitors that have entered into our plants. Work instructions are clearly visible on every machine to ensure that our employees are always aware of safety procedures while operating machines.

Customers

For food and beverage (“F&B”) division, food safety for our customers is the Group’s top priority. In order to achieve this, we have been granted the certification as below:

- BRC global safety standard

- Hazard Analysis, Critical Control Point (“HACCP”)

- Makanan Selamat Tanggungjawab Industri (“MeSTI”)

- Good Manufacturing Practive (“GMP”)

- HALAL certification

- NASAA certified Organic

- USDA Organic

- ISO 9001 (QMS)

- ISO 22000 Food Safety Management

- Organic Food Chain (OFC)

The process of certification includes adequacy, compliance and follow up audits by appointed certified external auditors.

Communities

The Group also believes in giving back to the community through participating in CSR activities. During the year, Thong Guan has demonstrated our commitment towards discovering Orang Asli village to understand how they live and survive in the forest.

We have made a visit to Orang Asli village located in Belum Temenggor, Perak which the Jahai Group belonging to the Negrito tribe lives. They have continued to live off nature through hunting, fishing and gathering jungle products as their main source of livelihood. Thong Guan has engaged the villagers in fun activities involving their children and has further distributed bags of daily food necessities to them.

The Group has also contributed to the various social bodies and schools for their charitable or sports activities include St John Ambulance Malaysia, Persatuan Ping Pong Amatur Kedah Tengah, Lions Club and others.

Sustainability Matters of Environmental Interest

At Thong Guan, we believe that environmental sustainability is as important as business sustainability. The Group is seeking to comply with environmental regulations and enhance corporate environmental responsibility efforts. With this objective, we are certified with ISO 14001 which is the most widely used standard for Environmental Management Systems internationally. By implementing the standard, we are able to manage the environmental impacts during conducting our business activities.

Minimising wastage of resources

We have in place, our nano-technology stretch film machine which is designed to be safe and efficient through a fully computerised manufacturing process to reduce energy consumption and minimise waste in production process.

Through our collaboration with one of our subsidiaries – Newton R&D Centre Sdn Bhd on ENGAGE programme, we aim to optimise the stretch film application and improve our bottom line as the nano-technology stretch film could provides guaranteed lower consumption of raw material per wrap and stabilisation of load over time.

Our data and analysis are tabulated through a series of testing from cutting edge machines and real time stimulations which will then allow for recommendations to the Group for best designs and package techniques for load stability and safety.

Waste recycling

We have in place, Standard Operating Procedures (SOPs) and Work Instructions to ensure the best possible measures are taken throughout all our facilities to reduce any adverse environmental impacts arising from the discharge of waste.

Within the Group of companies, we have three production facilities which is equip in house recycling machines. This has enabled us to immediately recycle the side trim or rejected products arose from the daily manufacturing processes into recycle resin. The recycle resin will subsequently use back into our manufacturing processes in producing certain plastic packaging products. With this arrangement, the company is able to achieve zero material waste in the manufacturing process and achieving objective of “reduce” and “recycle” in the 3Rs concept.

The company has gone further steps in recycling. The resin material bag and other recyclable packaging materials that we have received from raw material purchases are also being collected, segregated and subsequently converted into recycle resin. In Year 2019, the Group has converted a nearly 400MT of material bag wastes into recycle resin.

For other hazardous waste from the manufacturing activities, the waste collected will be disposed by licensed hazardous waste recycling operator.

In Year 2020, the Group aim to extend the waste recycling initiative into supporting departments in office. The wastes from the supporting department will be segregated into 4 bins which include paper bin, plastic bin, metal cans bin and general waste bin. The money collected through disposal of waste is then channel to use in CSR activities.

Preserving the environment

For energy consumption, the Group has been continuously devoting efforts to reduce the usage of the electricity, we have continuously engaged a certified electricity consultant to perform an analysis and to provide solutions to further reduce the usage of electricity apart from our current initiatives.

In Year 2019, we have continued to implement the Green House Gas Emission (GHG) project by installed another 2 photovoltaic solar systems on the roof of our factories to generate electricity. This project generates electricity from sunlight via the solar PV system installed. Solar PV system is deemed as “emission free” system because its operation does not emit any carbon dioxide or greenhouse gas. With the implementation of this solar PV system technology, it will reduce our carbon footprint and deliver economic savings to the Group.

The photovoltaic solar systems on the roof of our factories have reduced the greenhouse gas emission totalling to 5,322.51 tCO2e/yr, which equivalent to 26,609 trees offset/yr. The Group aim to continue with new installation of PV solar systems for other subsidiaries in Year 2020 to further increase the reduction of greenhouse gas emission throughout the Group.

Moving Forward

In conclusion, our sustainability statement reports all the economic, environmental and social risks faced by the Company in this financial year. The statement also extends to the management and the efforts put in by the Company to grow as an exemplary sustainable organisation. Moving forward, we will continuously endeavour to enhance our sustainability performance in the coming years.