In the past decade, the use of nanotechnology has been rapidly increasing in the field of stretch films.

It has revolutionised the way stretch films are produced.

Nano stretch films created using nanotechnology allow for a much thinner and stronger film than traditional stretch films.

The production process for this type of film involves using advanced technology and techniques to create a product that can be used for various applications.

This article will discuss the production process for nanotechnology-layered stretch film and how it can benefit us.

Nano stretch film is produced by layering multiple nanoscale layers of polymer molecules together, resulting in a much more durable and flexible material.

The process involves depositing and bonding polyethene (PE) or other polymers in a vacuum environment to form ultra-thin films. This makes nano-stretch film ideal for packaging, storage, and transportation.

Production line where polymer molecules are extruded into nanoscale layers.

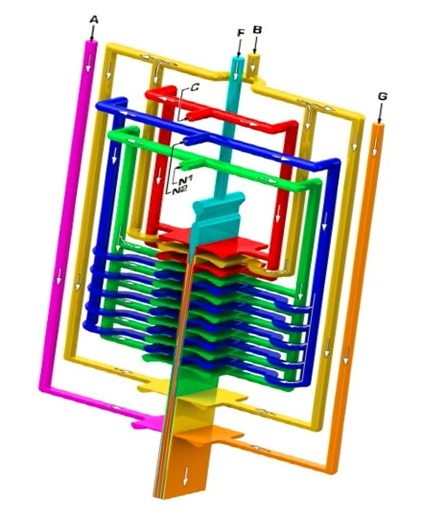

A typical nanostructure flow where each colour represents different raw materials are injected from 7 extruders

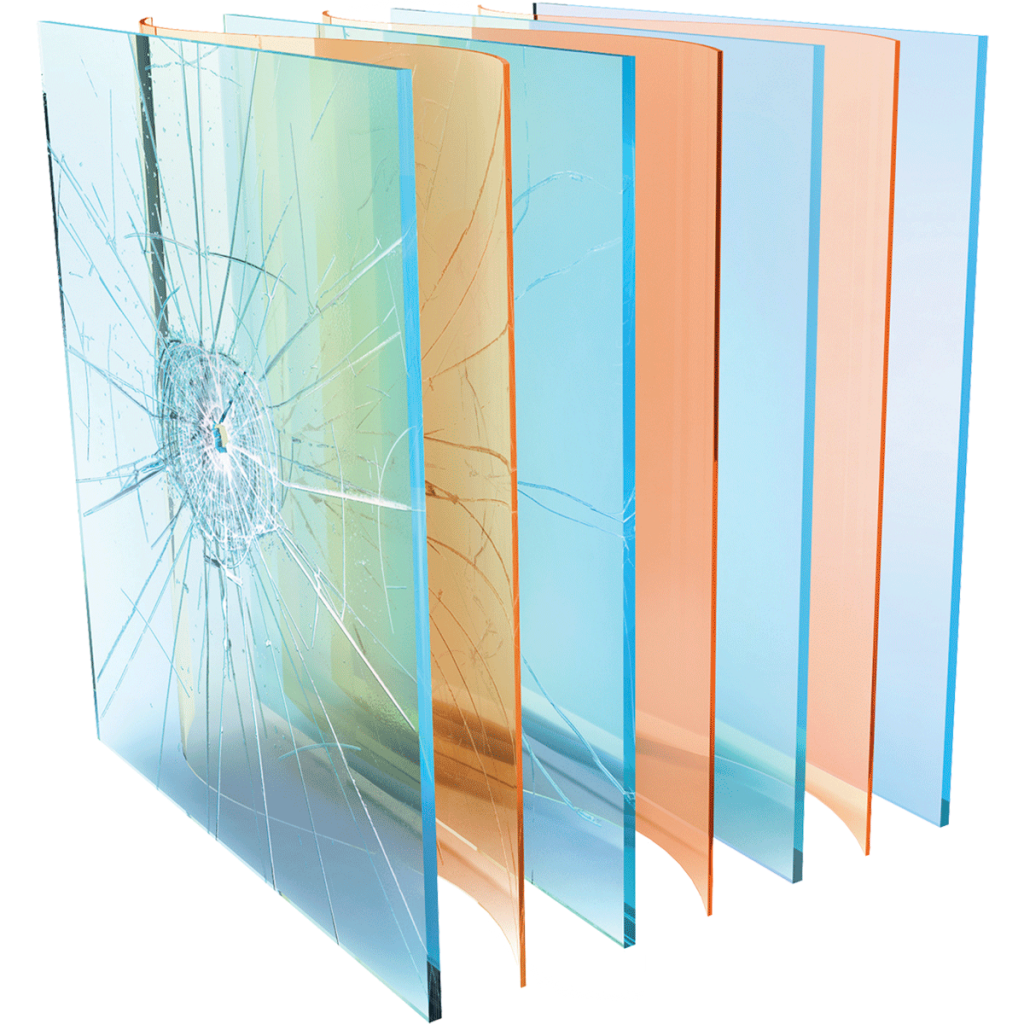

The film works by combining the properties of the multiple layers, resulting in a strong, flexible, and tear-resistant material.

The nanolayered film has better stretch and cling properties than multilayered stretch films, making it an efficient wrapping material for pallets and other items.

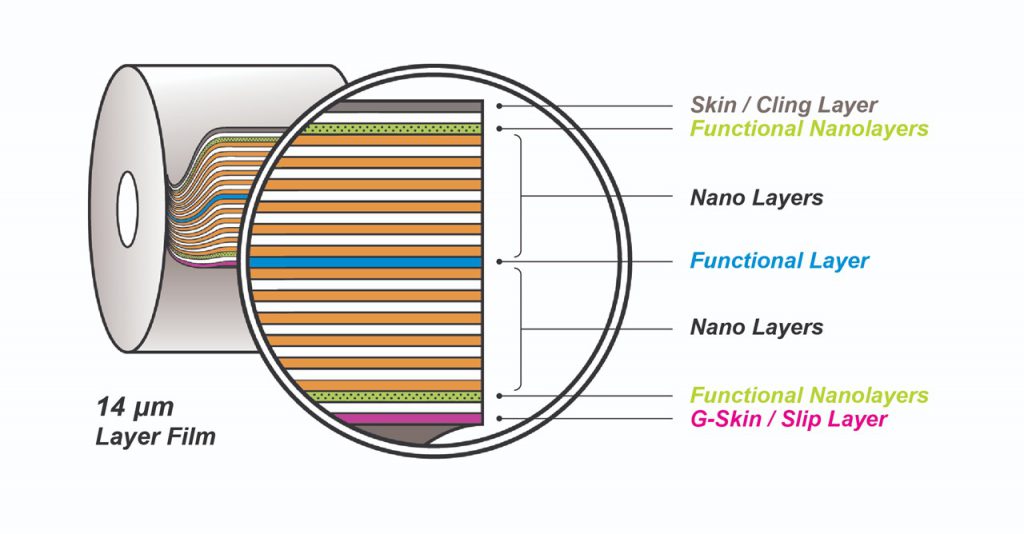

The make-up of a typical 14 µm nanolayers film.

The process also involves applying additives to enhance specific properties such as strength or flexibility.

The result is a highly durable product that provides superior protection against punctures and tears while being lightweight and easy to handle.

The benefits of using nano-layered stretch film include increased load stability, reduced film usage, and improved product protection. It also reduces plastic waste, requiring less film to secure the same load.

Additionally, the film’s strength and flexibility make it easier to handle, and it can improve the overall efficiency of the packaging process.

The advantages of nano stretch film include

- Stronger and more flexible than multilayered stretch film

- Reduces the amount of film required to secure a load, reducing plastic waste

- Improved cling and stretch properties, making it easier to wrap packages securely

Nano-layered and multilayered stretch films are similar in that they both consist of multiple layers of polyethene or other polymers.

However, the key difference lies in the thickness of the layers. Nano-layered stretch film has ultra-thin layers on the nanoscale, while multilayered stretch film has thicker layers.

Both nano-layered and multilayered stretch film work by combining the properties of the multiple layers to create a stronger, more flexible, and tear-resistant material.

The multiple layers distribute the load across the film, reducing the risk of tearing or puncturing.

The film’s cling properties help keep it securely wrapped around packages, preventing them from shifting during transit.

However, with the nanoscale layer produced using nanotechnology, we can easily increase the number of layers to improve the film’s performance while retaining the ultra-thin property.

Thus, giving us added advantage over mere multilayered films.

Nano stretch film with many nanolayers can offer improved performance compared to multilayered stretch film, making it an attractive option for packaging applications with high strength, flexibility, and cling properties are required.

The film is also more environmentally friendly, as it uses less material to secure a load, reducing the amount of plastic waste.

Overall, nano stretch film with a high number of layers represents a technological advancement in stretch film technology and has the potential to offer improved performance and sustainability benefits in various packaging applications.

In the past 6 years, Thong Guan has refined their nano stretch film development from 33 layers to 67 layers, improving quality performance to serve the market needs.

Thong Guan is also the first film producer in Malaysia to be audited and certified with NanoTrusted, a mark indicating the authenticity of their nano stretch film to be at the true nanoscale level.

If you have any questions on nano stretch film and its performance, please contact David Ang at davidang@thongguan.com or Christian Olesen at chr@tgeurope.dk.

You can also drop us an email at info@thongguan.com.