Brand owners have invested heavily in packaging optimisations to ensure their goods are well protected during transportation. The reason is obviously to reduce unnecessary cost leakage.

From primary to tertiary packaging, industry players and brand owners have worked together for ages to ensure the most optimum packaging design and wrapping methods.

All in the efforts to prevent film breakages, packaging compromise and product damages that lead to unsaleables, transportation safety, and environmental factors.

On that topic itself, Thong Guan and Newton Lab have covered heavily on the ways to optimise and prevent film breakage over the years. A quick search on the Internet also brings you ample information on the topic.

However, there is one particular film breakage factor that is not being paid attention to often—and that is load-to-load transportation film breakage.

Load-to-load contact occurs when pallets are stacked together at stores or warehouses, ready to be transported for distribution. Naturally, pallets that are placed side by side will cling together, all thanks to the power of the clinginess of the films.

However, with high-slip stretch film, instead of the pallets gripping each other, they will slide off each other bringing ample benefits to brand owners.

What is Nano-Layered High Slip Stretch Film and How Does it Help with Packaging?

Nano-layered high slip stretch film is a type of stretch wrap with

- a high level of “slip” surface for ease of movement between the layers of the film on packaged items and

- an aggressive cling surface for wrapping loads onto pallets for transportation ease.

With the benefits of nano and slip technology, brand owners can enjoy the best of both worlds for not just optimum wrapping but also process efficiency.

It makes applying easier and provides better load stability than standard stretch films. High slip film also helps to reduce packaging time and waste, improve load retention, enhance load clarity, and increase efficiency and productivity in the warehouse.

How High Slip Stretch Film Enhances Warehouse Efficiency & Productivity

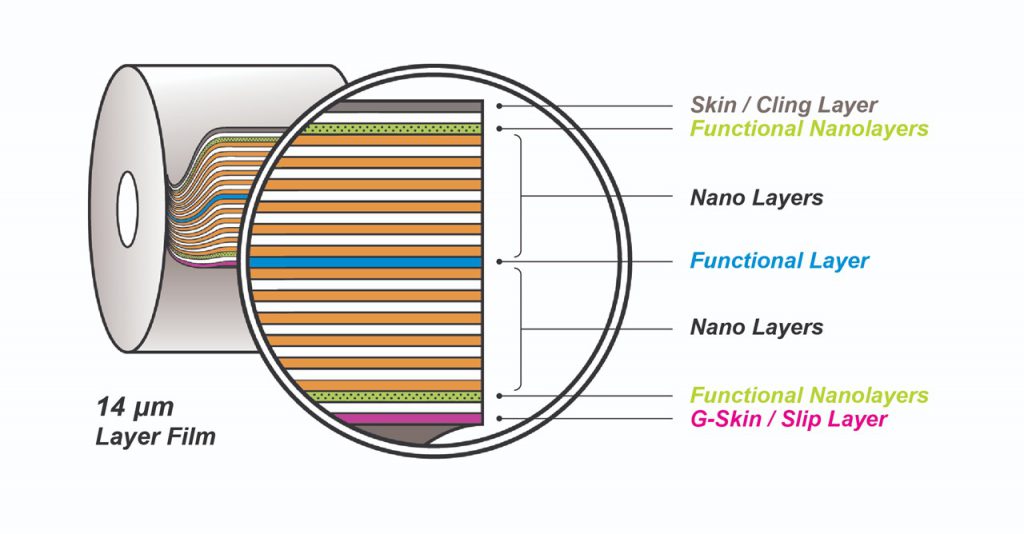

Nanotechnology offers great potential in film conversation, enabling the creation of advanced materials and speciality film. In the case of high-slip stretch film, nano-technology is used to create a unique, multilayer film that provides both a smooth and slippery outer layer and a gripping inner layer. This allows the product to be securely wrapped on the pallet and easily transported without the risk of load-to-load contact and film breakage.

High-slip stretch film enhances warehouse efficiency and productivity by reducing the time and resources needed to rewrap damaged loads. The smooth and slippery outer layer also allows for easier and faster wrapping of pallets, reducing labour time and costs.

Compared to standard nanofilms, high-slip nano stretch film has several advantages. The multilayer construction provides better load stability and protection during transportation, while the smoother outer layer reduces the risk of damage to the product. Additionally, the high-slip film requires less tension to be applied during wrapping, reducing the risk of operator strain injuries and allowing for more consistent and efficient wrapping.

Nano Glide is a high-slip stretch film that utilises nano-technology to provide enhanced load stability, reduced risk of damage, and improved warehouse efficiency. Whether you are a logistics professional, warehouse manager, or supply chain expert, Nano Glide is the perfect solution for your packaging needs.

An added advantage of high-slip stretch film is the low noise pollution typically caused by the friction between pallets during transportation for distribution.

So instead of this.

How about switching it out for this?

How to Choose the Right High Slip Stretch Film for Your Business Needs?

Selecting the proper stretch film is about more than just the film quality or the price per se.

Here is a list of things to be considered.

- Load weight: Choose a film with adequate strength and stretch to hold your specific load weight securely.

- Storage conditions: Consider film performance in extreme temperatures, humidity, and other storage conditions.

- Clarity: If showcasing your packaged items is essential, choose a film with high clarity.

- Puncture resistance: For packaging items with sharp edges or irregular shapes, choose a film with improved puncture resistance.

- Recyclability: If sustainability is necessary, consider a film made from recyclable materials.

- Cost: Consider the cost of the film and weigh it against the benefits it offers for your specific needs.

- Availability: Choose a readily available film that is compatible with your existing packaging equipment.

- Supplier reputation: Choose a reputable supplier with a proven track record of providing high-quality high-slip stretch film.

Consider Nano Glide

Consulting with a packaging expert or conducting a trial run can help you determine the best type of high-slip film for your business needs.

You can always contact us at info@thongguan.com to discuss your business needs.

Or you can always consider our latest addition to our range of high-quality, consistent performance stretch films, the Nano Glide. Visit www.thongguan.com/nano-glide for more info.