A wide range of materials is used for 3D printing. The purpose of having a large number of materials is to make sure that it is possible to do 3D printing on various types of products.

It also brings much-needed flexibility in the shape, texture, and overall strength of a product. However, the exact process of 3D printing on a particular product can greatly vary, depending on the product and customer’s requirements.

The 3D printing industry is a multi-billion industry. Materials like plastics, resins, metal and even powders are used for 3D printing.

Commonly used plastic products like stretch films and stretch wraps also hold great significance in everyday lives.

In this article, you will get to know the five major types of plastic used in 3D printing.

Usage of Plastic in 3D Printing

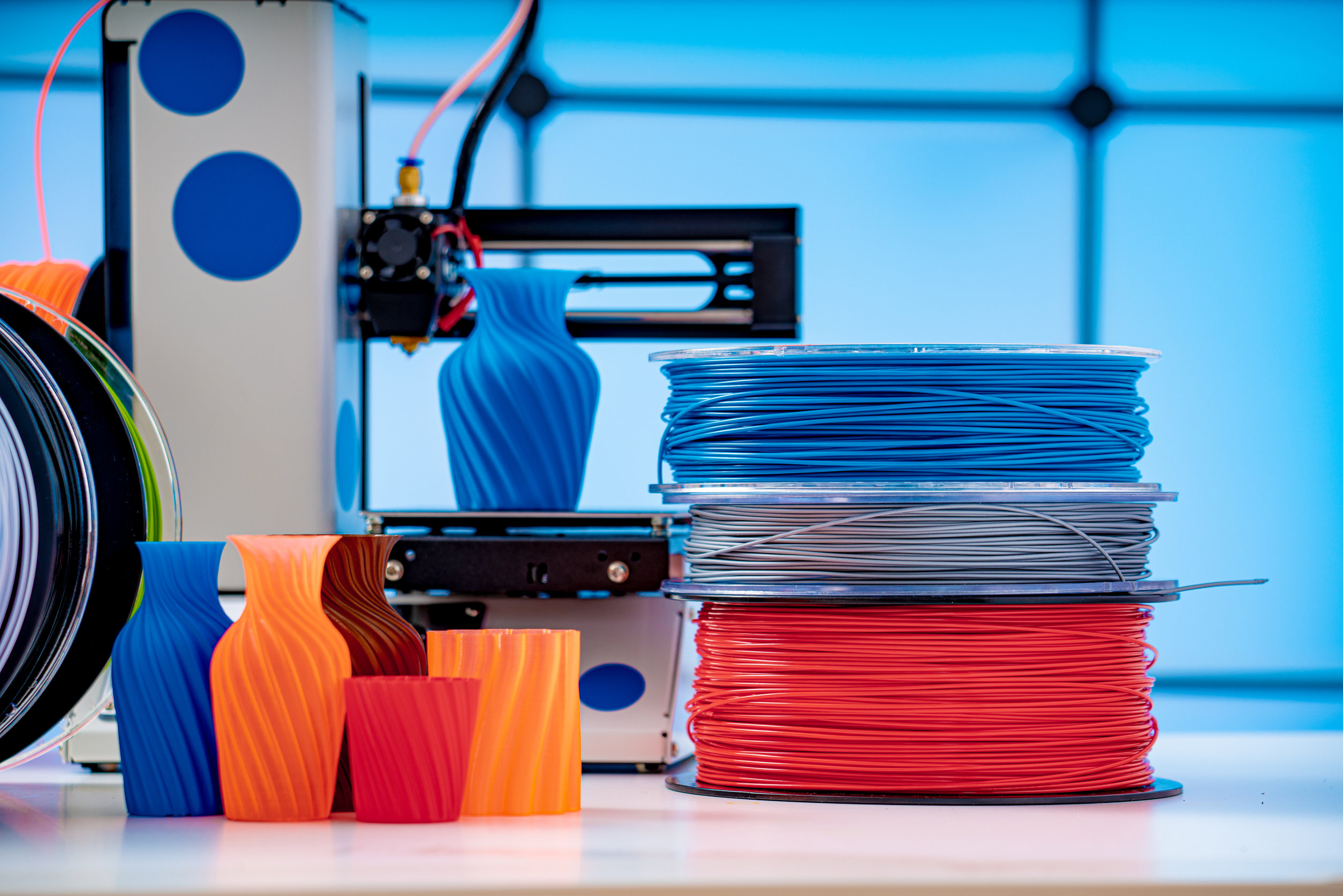

Plastic is the most common raw material for 3D printing. The benefit of using plastic is that it is a highly diverse material for 3D printed products like toys, household fixtures, desk utensils, and vases.

Furthermore, plastic materials are available in transparent form, as well as vibrant colours with different textures like matte or shiny textures.

The properties of plastic, like its strength, smoothness, and flexibility, have also played a critical role in increasing the applications of plastic in 3D printing. It is also a relatively cost-effective raw material to be used for 3D printing for both businesses and customers.

Generally, plastic manufacturers use fused deposition modelling (FDM) printers to produce plastic products and mold the plastic layer by layer, according to the desired requirements.

Following are the major types of plastics used in this process.

1. Polylactic Acid (PLA)

The use of PLA in 3D printing is rapidly increasing because it is one of the most eco-friendly options for 3D printers. It is extracted from natural products like sugar cane and corn starch. As a result, it is biodegradable.

PLA is available in both soft and hard forms, which means you can use it to make different types of products. Since hard PLA is stronger, it is used more to create a wide range of products.

It is highly expected that in the next few years, the use of PLA in the 3D printing industry will grow exponentially due to its reliability, quality, and eco-friendliness.

2. Acrylonitrile Butadiene Styrene (ABS)

ABS is commonly used for home-based 3D printers. It is known for its impressive safety and durability. ABS is also known as Lego plastic. The strength and flexibility of ABS are because it contains filaments similar to pasta.

The fact that ABS is available in multiple colours is also responsible for its popularity among different businesses. It is used to manufacture stickers, toys, vases, and jewellery. The use of ABS amongst craftspeople is rapidly increasing.

3. Polyvinyl Alcohol Plastic (PVA)

Unlike most other plastic materials, PVA is a water-soluble plastic typically used to produce a support structure for a product that can collapse during the printing process. Plastic manufacturers typically use PVA as a glue or packaging stretch film.

In order to enjoy the benefits of PVA, you must have a printer with two or more extruders so that one extruder can be used to create PVA while the other extruders can print the actual product made of another type of material.

Once the printing is completed, the finished product can be dipped in water to dissolve the PVA structure.

4. Polyvinyl Alcohol Plastic (PVA)

PVA is suitable for low-end home printers. However, some small businesses and startups can also use this material if they are operating with extremely limited resources.

PVA is not suitable for products that need high strength. Instead, it should be used for products that have temporary use and dissolvable quality.

5. Polycarbonate (PC)

PC is not a very common plastic material in the 3D printing industry because it works in specific 3D printers. Such printers must have suitable nozzle designs and be capable of operating at high temperatures.

A popular application of polycarbonate is to make moulding trays and affordable plastic fasteners.

In Closing

The benefit of having these many different types of plastic materials for 3D printing is that it is possible to produce various types of plastic items with the help of 3D printers.

Such items can be made in different shapes and sizes. Hence, the bottom line is that various plastic materials have different pros and cons. The plastic manufacturers select a suitable material to create a good-quality product with 3D printing.