Pallet hand-wrapping is a critical step in the logistics and supply chain industry, ensuring the safe and secure transport of goods. While automated wrapping machines have gained popularity, there are situations where hand-wrapping remains a necessity.

Continue readingSustainable Packaging in the Age of Consumer Consciousness

Explore sustainable packaging and consumer consciousness, revealing how eco-friendly solutions shape the future.

Continue readingThe Importance of Recycling for Sustainability in the Plastic Packaging Industry

Delve into the crucial role of recycling in the plastic packaging industry. Learn why recycling is essential for sustainability and the environment.

Continue readingRedefining High-Speed Wrapping: Velocity—The NEXT Ultra-Thin, Tough Stretch Film

Introducing Velocity, the ultra-thin, tough stretch film that is set to redefine your high-speed wrapping and improve your sustainability.

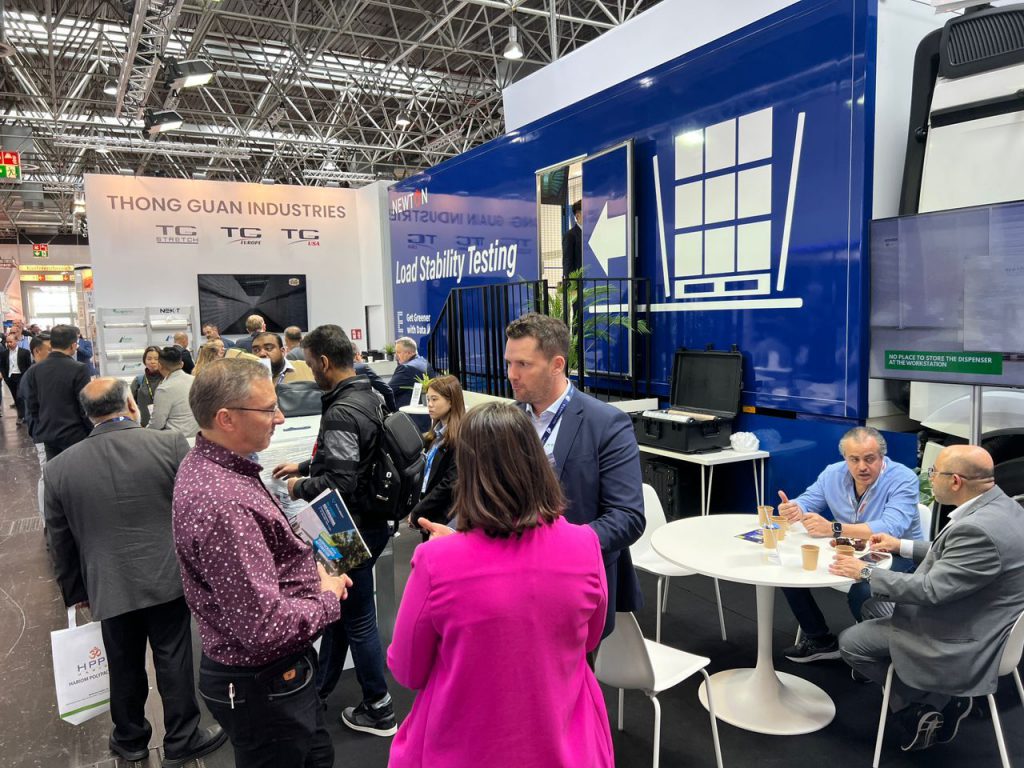

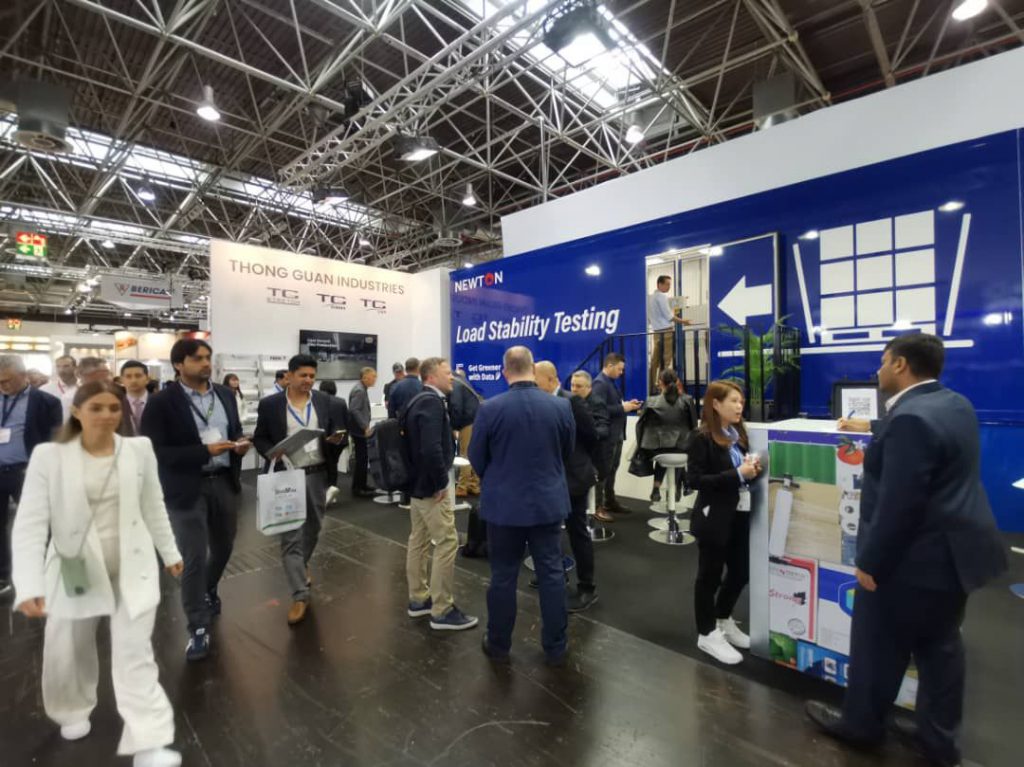

Continue readingThong Guan Takes Load Stability Testing to New Heights at Interpack 2023

Thong Guan Industries Berhad, renowned for its relentless pursuit of innovation to meet the dynamic needs of the market, made a lasting impact at Interpack 2023.

Continue readingHow Thong Guan Supports the Paris Agreement

Thong Guan’s Support for the Paris Agreement: A Sustainable Partnership

Continue readingLoad Stability On The Move: A Game-Changer for Packaging Testing

How Is Plastic Resin Made – Exploring the Process

Demystifying the Process of Plastic Resin Production

Continue readingWhat are the Best Tips for Pallet Wrapping Techniques?

Find out what makes recycled shrink film a great choice for your packaging needs.

Continue readingThe Promise of Nanotechnology in Stretch Films: Unlocking Endless Possibilities

Nanotechnology has revolutionised the way stretch films are produced. It allows for a much thinner and stronger film than traditional stretch films. This article discusses the nanotechnology stretch film production process and how it can benefit us.

Continue reading