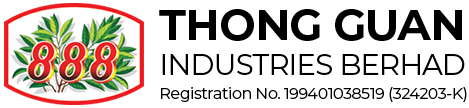

Pallet wrapping machines are designed to improve efficiency, load stability, and safety—but only when they are used correctly. Many warehouses and manufacturing facilities invest in a pallet wrapping machine expecting immediate cost savings, yet still experience film waste, damaged pallets, frequent downtime, or even workplace accidents.

Why does this happen?

In most cases, the issue is not the machine itself, but how it is operated, maintained, and paired with pallet stretch film.

This article breaks down the essential do’s and don’ts of wrapping machine use, helping businesses avoid costly mistakes while maximising performance, safety, and long-term efficiency.

Why Correct Wrapping Machine Use Matters

A pallet wrapping machine plays a critical role at the end of the packaging line. It secures goods for storage and transport, protects products from damage, and ensures stable loads throughout the supply chain.

Improper use can lead to:

- Excessive pallet stretch film consumption

- Unstable loads during transport

- Product damage and returns

- Safety hazards for operators

- Increased maintenance and repair costs

Understanding correct operation is not just about efficiency—it’s about protecting people, products, and profits.

The Do’s of Using a Pallet Wrapping Machine

Do Understand Your Load Characteristics

Not all pallet loads are the same. Before setting machine parameters, operators must understand the weight, height, shape, and fragility of the load.

Loads with sharp edges, uneven surfaces, or varying weight distribution require different wrap tension and film layering. Adjusting the machine to suit each load type helps prevent film breakage and load instability.

Taking time to assess the load ensures the pallet wrapping machine performs optimally for every application.

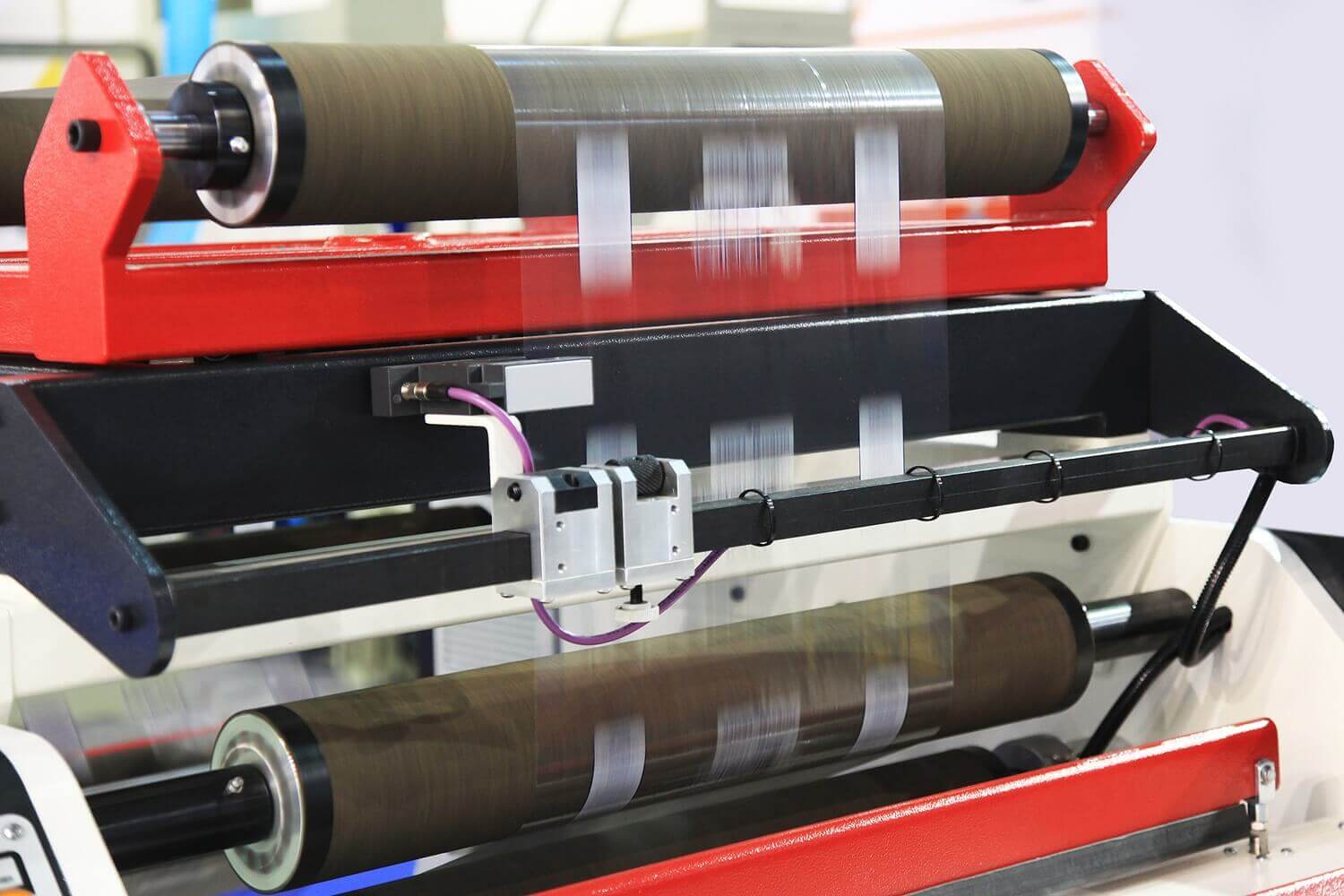

Do Use the Right Pallet Stretch Film for the Machine

One of the most common mistakes is using the wrong type of pallet stretch film. Films designed for hand wrapping often lack the strength and elasticity required for machine use.

Machine-grade pallet stretch film is engineered to:

- Withstand high pre-stretch levels

- Maintain consistent tension

- Provide reliable load containment

- Reduce film breaks during automated cycles

Using the correct film ensures smoother machine operation and better wrapping outcomes.

Do Optimise Pre-Stretch and Tension Settings

Pre-stretch settings directly affect film efficiency and load stability. A properly calibrated pallet wrapping machine stretches the film before application, allowing it to wrap tightly while using less material.

Optimised settings help:

- Reduce pallet stretch film usage

- Improve load containment force

- Minimise film tearing

- Maintain consistent wrapping quality

Regularly reviewing and adjusting these settings is key to long-term cost control.

Do Follow Safe Operating Procedures

Safety should always be a priority when operating a pallet wrapping machine. Operators must be trained to understand machine controls, emergency stop functions, and safe working distances.

Basic safety practices include:

- Keeping clear of rotating parts

- Avoiding loose clothing near the machine

- Ensuring pallets are correctly positioned

- Never bypassing safety guards

A safe environment reduces downtime and prevents workplace injuries.

Do Perform Regular Maintenance Checks

Routine maintenance keeps wrapping machines running smoothly. Small issues—such as worn rollers or misaligned film carriages—can quickly escalate into costly breakdowns if ignored.

Maintenance tasks should include:

- Inspecting moving components

- Checking film carriage alignment

- Cleaning sensors and rollers

- Lubricating mechanical parts as recommended

Preventive maintenance protects both the pallet wrapping machine and the pallet stretch film used.

The Don’ts of Using a Pallet Wrapping Machine

Don’t Over-Wrap Pallets “Just to Be Safe”

A common misconception is that more film equals better protection. In reality, over-wrapping increases material costs without necessarily improving stability.

Excessive pallet stretch film can:

- Waste material

- Increase wrapping cycle time

- Add unnecessary weight to shipments

- Create disposal challenges

Correct tension and wrap patterns provide better results than excessive layering.

Don’t Ignore Load Instability Signs

If wrapped pallets lean, shift, or show loose film layers, this is a warning sign. Ignoring these indicators often leads to damage during transport or storage.

Signs of instability include:

- Sagging film

- Uneven wrap tension

- Pallet edges exposed

- Film tearing during handling

Addressing these issues immediately prevents larger supply chain problems.

Don’t Use One Setting for All Loads

Using a single wrap program for every pallet may seem efficient, but it often leads to poor results. Different products require different wrapping strategies.

Rigid loads, mixed cartons, and lightweight items all behave differently under tension. Customising settings for each load type ensures better performance and fewer errors.

Don’t Neglect Operator Training

Even the most advanced pallet wrapping machine cannot perform well without trained operators. Inadequate training often results in improper film loading, incorrect settings, and unsafe practices.

Training should cover:

- Film threading techniques

- Control panel functions

- Load assessment

- Basic troubleshooting

Well-trained operators improve efficiency and reduce mistakes.

Don’t Overlook Machine–Film Compatibility

A mismatch between the machine and pallet stretch film can cause frequent film breaks and inconsistent wrapping. Films with insufficient strength or elasticity may fail under high pre-stretch settings.

Ensuring compatibility between the wrapping machine and film type helps maintain smooth operation and consistent load stability.

Safety Mistakes That Can Lead to Serious Consequences

Operating a pallet wrapping machine without proper safety awareness can result in serious injuries. Common safety mistakes include:

- Standing too close during rotation

- Attempting manual adjustments while the machine is running

- Bypassing safety interlocks

- Improper pallet placement

Following manufacturer safety guidelines and enforcing standard operating procedures protects both operators and equipment.

How Correct Machine Use Reduces Long-Term Costs

When pallet wrapping machines are used correctly, businesses experience measurable cost savings across multiple areas:

- Reduced film consumption through optimal pre-stretch

- Lower product damage rates due to stable loads

- Improved labour efficiency with fewer rewraps

- Less machine downtime from reduced wear and tear

- Safer workplaces with fewer accidents

These benefits compound over time, making proper machine use a strategic investment rather than a simple operational task.

Common Wrapping Mistakes and How to Avoid Them

Many wrapping issues stem from simple oversights. Examples include:

- Using damaged pallets that compromise stability

- Failing to anchor film properly at the pallet base

- Wrapping too high or too low on uneven loads

These mistakes can be avoided by following basic best practices and performing routine checks before starting each wrapping cycle.

The Role of Technology in Preventing Mistakes

Modern pallet wrapping machines increasingly feature automated tension control, programmable wrap patterns, and safety sensors. These technologies help reduce human error and improve consistency.

However, technology is only effective when users understand how to use it correctly. Combining automation with proper training delivers the best results.

Final Thoughts: Smart Wrapping Starts with Smart Practices

A pallet wrapping machine is a powerful tool—but only when used correctly. Avoiding common mistakes, selecting the right pallet stretch film, and maintaining proper operating practices can significantly reduce costs, improve safety, and enhance load stability.

By focusing on correct usage rather than quick fixes, businesses can unlock the full value of pallet wrapping automation and build a more efficient, reliable packaging operation.

Thong Guan Packaging Solutions

Discover Thong Guan’s innovative packaging solutions designed to protect your products and the planet. From high‑performance stretch films to sustainable food wraps and flexible packaging, we deliver quality, reliability, and eco‑friendly excellence. Partner with us today to secure your goods, enhance efficiency, and embrace sustainability with confidence