Did you know that 4% of transported goods are damaged upon arrival? Factories, warehouses, and businesses are now more aware of the importance of optimized packaging when it comes to pallet wrapping machines to avoid unwanted losses.

While buyers are concerned about the condition of the goods they paid for, sellers are much affected and responsible for this.

Even if damage did not occur at the seller or senders center, the primary fault usually goes to them, resulting in costly return cost and damage to their reputation.

This is why optimizing your tertiary packaging is the way to help improve what you are already doing but better.

What Is Optimized Packaging?

In a nutshell, packaging optimization means using smart packaging that fits your packaging needs designed to secure, contain, and protect your products.

It is important that your packages are secured during logistic processes from warehouses, factories, in-store fulfillment centers, or manufacturers to a final destination usually determined by the buyer or due process.

What Should I Be Looking at For Optimized Unitization?

So, what does optimization mean? Optimized packaging means using the right film for the suitable machine for the right amount of film when it comes to stretch film.

The Right Amount of Film

Too thin of a film, and it will not protect the product. Too thick, and it will cost more and potentially damage the product if it’s packed too tightly.

Optimizing a pallet properly depends on the film’s pre-stretch capabilities and the heaviness of the load.

For example, when wrapping a heavy pallet of drinks of 1.5L bottle packs x 480 bottles per pallet, Newton R&D Center’s benchmark would be to use 450 grams of stretch film for optimum wrapping. If it is a smaller packed 500ml bottle packs x 1,200 bottles per pallet, our best benchmark is that your stretch film usage should only weigh 408 grams.

What about lighter pallet wraps?

Light package wraps like packaging a pallet of tissue should be wrapped using a ring wrapper should only require 280-300 grams of stretch film (according to Newton R&D Center’s benchmark).

The Right Machine

As covered in our previous article on pairing your film to the right stretch wrapping machine, it is essential to match them to achieve optimum wraps.

In summary, these machines are generally used and suitable for your wrapping needs

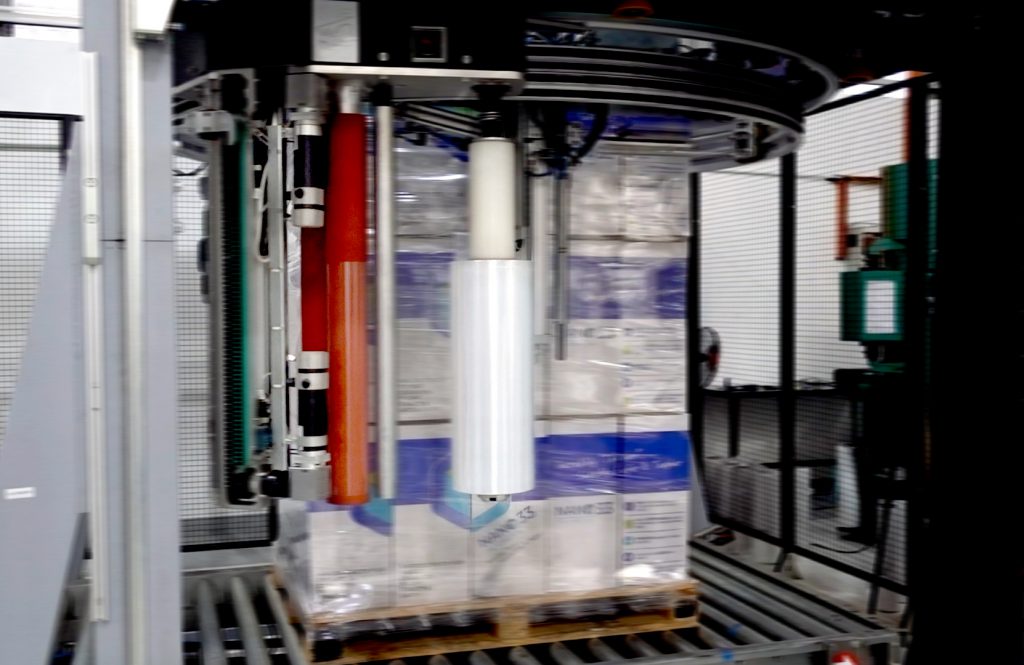

Turntable Wrapper – The simplest form to wrap where the pallet is placed on a turntable that rotates while a pallet stretch film is delivered around the load. It is capable of 10– 20 loads per hour and ideal for A and B load types.

Rotary Arm Wrapper – Operates by positioning loads under a rotating arm. The load stays secured and stationary while stretch film is revolved to wrap around the pallet. Suitable for all A, B, and C types of heavy and oversized loads.

Ring Wrapper – Excellent for unstable loads that required high throughput yield. When wrapping, the load remains stationary. The wrapping is done via rotating around the pallet not by an arm but through a large ring.

Benefits of optimizing wrapping

What are the benefits of packaging in supply chain management when optimizing wraps? Here are some important ones that could benefit you:

Save cost – Don’t spend unnecessarily for more film when you can do better with less.

Good for the environment – You are not over or under-consuming when you are optimizing. When you over-consume, access materials contribute to more wastage (more carbon footprint), while under-consuming isn’t a healthy option. When there is not enough film to optimize your wraps, your pallets become unstable and are prone to tip over and all, resulting in damaged and unsaleable goods.

Enhance Production – Optimized wrapping can increase production in warehouses or distribution centers when there is no overwrapping of pallets. This saves time and boosts output.

Minimizing product damage – With optimized wraps, you gain better load stability and containment. There will be lesser chances of damages in your warehouse and along the distribution journey.

Increase employee productivity – Employees will also find it easier to handle packages that are optimized too. Packing is neat, tidy, and easy to handle too.

Using Machines to Optimize Your Wraps For Optimized Packaging

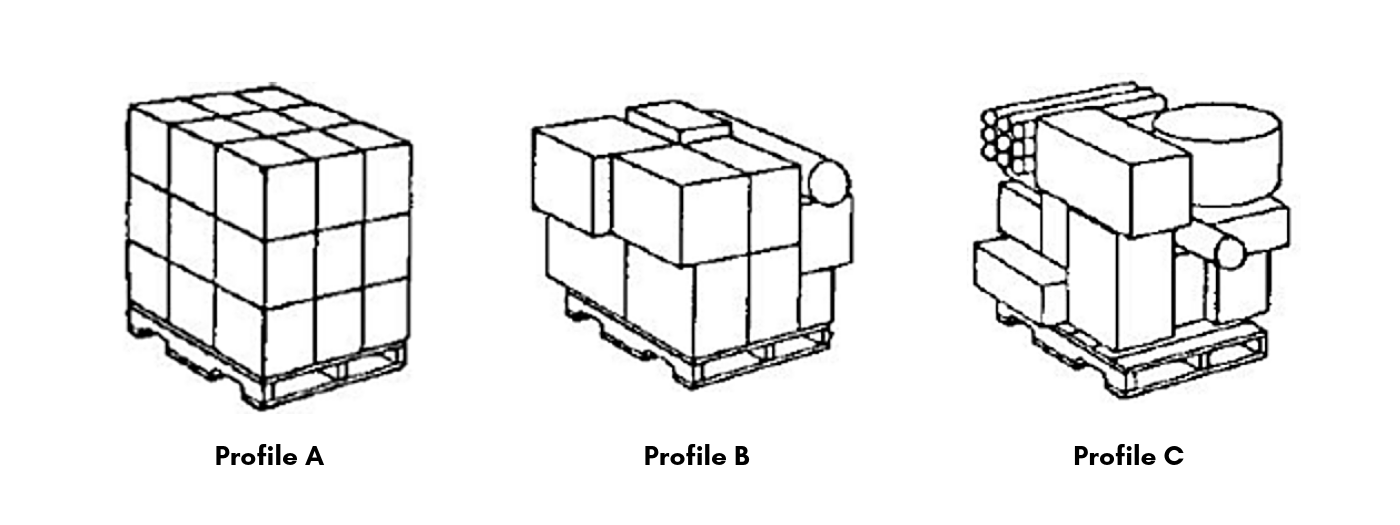

Different machines work with different types of loads. Generally, there are three types of pallet wrapping loads:

A Load – Stable, straight sides with up to 3″ protrusions.

B Load – Relatively stable with protrusions of up to 6″ inches or less

C Load – Oddly shaped with several protrusions (including sharp corners) of over 6″. Unstable.

How Do Thong Guan’s Products Fit into Your Load Type?

Optimizing your loads can be quite a challenge, and we are here to help you with it. Here are some scenarios of how our machine film products can level up your wrapping process. If you already:

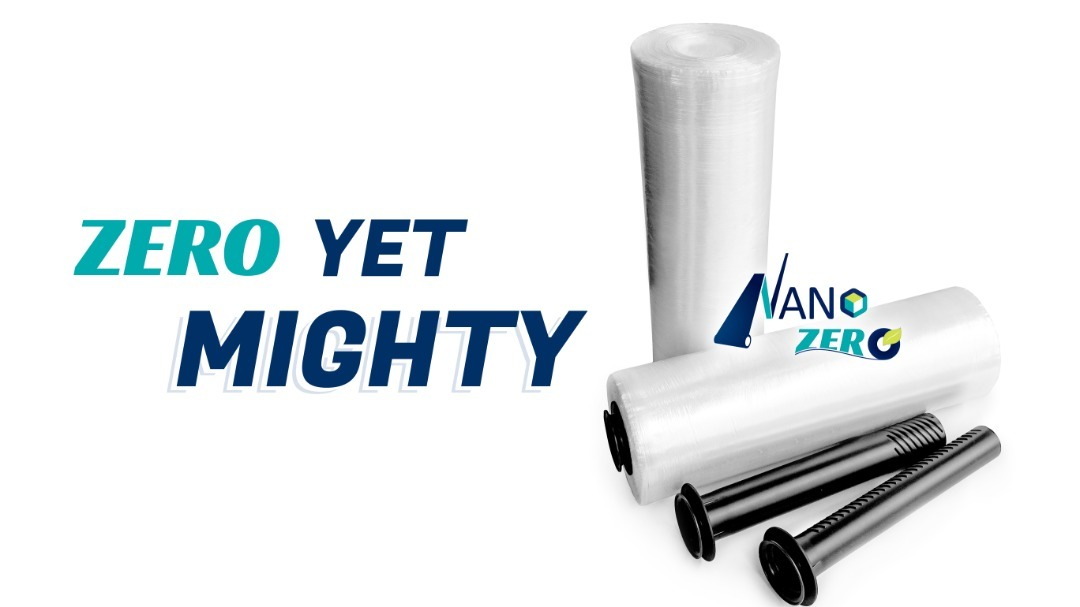

Have your own machine, but your machine doesn’t pre-stretch much (less than 100%)?: Don’t worry, you don’t have to convert your machines to power pre-stretch yet. Our Maxstrech series would be best suited for such applications. Maxstretch comes with a 20% guaranteed load integrity/memory that is stiff for optimal load containment. With less film consumption, it helps you save cost and gains the best for your wraps.

Have your own power pre-stretched machine that can pre-stretch 300% using 23um film?: Thong Guan’s NanoXecure is perfect for you. Xecure is a high holding force film at a thinner gauge where 14um film would handle and perform the same as a typical 20um film. Xecure’s 17um film can also efficiently perform as well as 23um films. Our nano series films are designed to have high holding force but with a thinner gauge so that you can save on film.

Have an inline machine for fast wrapping environments?: When in high-speed wrapping environments, there must be no failure of film. Thong Guan’s Nano55 soft film pre-stretched up to 300% is designed for total cost savings and most suitable in such fast-paced wrap settings.

So How Do We Select the Best Film?

Still unsure about selecting the right film for your stretch film machine for optimized packaging? Thong Guan has worked with Newton R&D Center to help factories, warehouses, distribution centers to select the right film with our Engage program.

It is an effective seven steps program, which can help you make the right decision on selecting the right film

Alternatively, Newton R&D Center also has a program called protection plus, which is similar to our Engage program.

Time to Engage: Optimize Packaging Solutions Today

The way you use your stretch film can significantly decrease potential damages, wastages, and unsalable goods. On the upside, it can also boost profit and increase customer satisfaction too.

Remember: Optimize packaging starts with choosing the correct film, using the right amount of film, and utilizing the best wrapping method suitable for your packing needs.

Having peace of mind when your loads leave your facility is easy.

Let’s connect to show you how. Together we can optimize your wrapping process and increase your output to get the best value in return.

Wait no more, engage us.

Contact us at info@thongguan.com for more info or to enquire more today.