Plastics that have #1 (PETE) or #2 (HDPE) are the most commonly recycled plastics.

Continue readingInnovation Ideas to Solve Plastic Packaging Problems

Today, more people have become eco-conscious and they prefer to buy eco-friendly products or products that come with eco-friendly packaging.

Continue readingPlastic Resin Report and Trend: Are Prices Up for This Year?

Even though plastic wraps are normally used for preserving food, there are many other uses that are not commonly known.

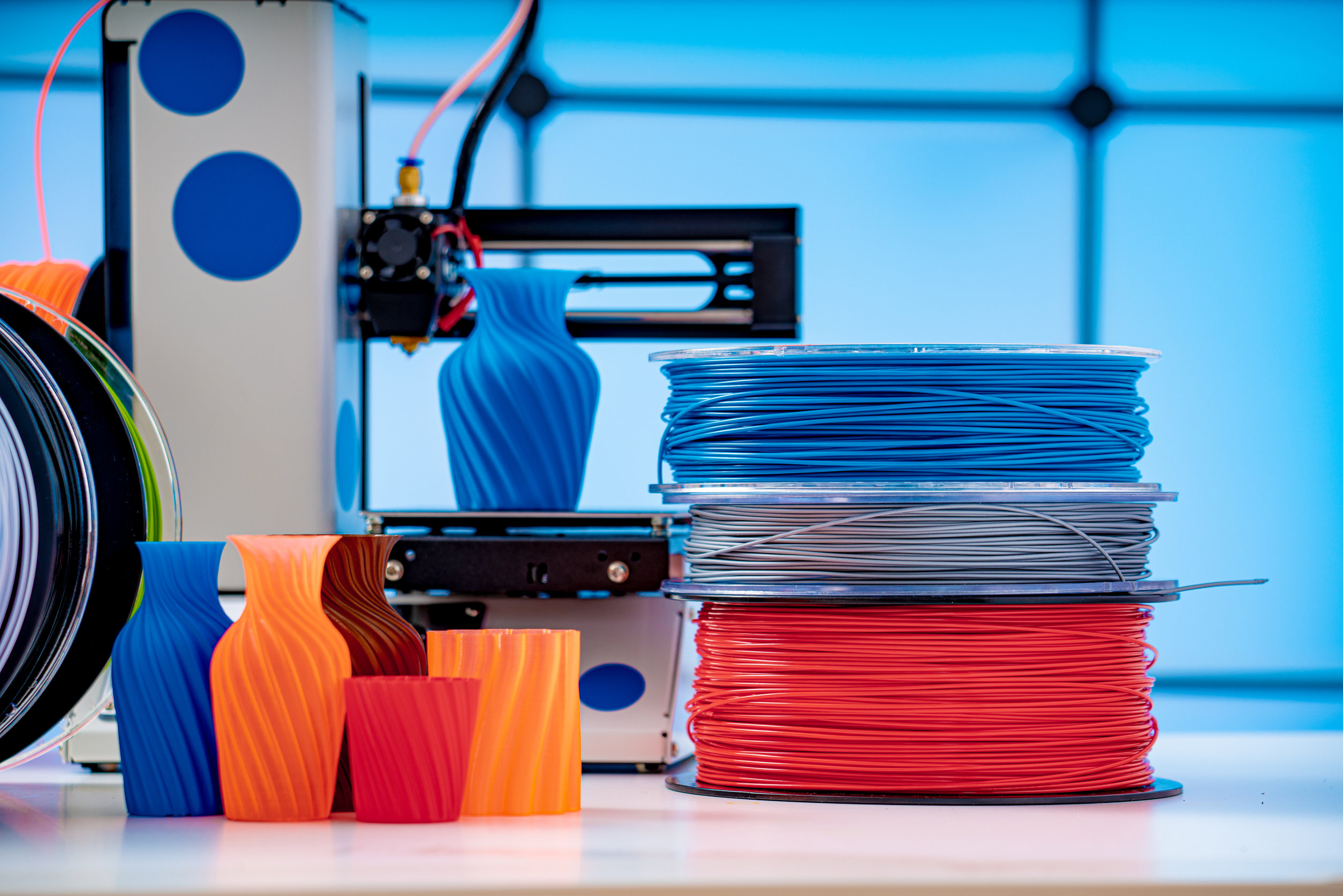

Continue readingWhat Types of Plastic are Used in 3D Printing?

Even though plastic wraps are normally used for preserving food, there are many other uses that are not commonly known.

Continue readingPlastic Market Industry 2022: Analytics and Forecast

The global plastics industry is on the path of continuous growth because of massive demand.

Continue readingTips to Protect Your Belongings from a Flood

Keep reading this post to learn how you can protect your belongings from a flood.

Continue readingSurprising Uses For Plastic Wrap: Not Just For Food Only

Even though plastic wraps are normally used for preserving food, there are many other uses that are not commonly known.

Continue readingThe New Normal for Packaging Design: Post Covid-19 Pandemic

When introducing new packaging, keep a consumer-safety mindset in mind.

Continue readingHow to Make Your Food Last Longer in the Refrigerator

A refrigerator is more than simply a box that keeps food cold. It’s a high-tech device that employs sophisticated controls to keep humidity, light, and temperature at optimum levels for food storage.

Food wrap is essential for keeping food fresh, safe, and odourless until it’s time to eat. Mould and mildew can spread if foods aren’t stored correctly, so odours are only one aspect of the problem.

It is possible to retain nutrients and guarantee that meals do not grow stale by learning to store foods in the correct areas of the fridge using plastic food wrap.

Beyond helping to store your food, food wraps also give your food a beautiful look in the refrigerator.

For example, if you are into selling packaged goods on store shelves, Thong Guan’s Klarity plastic food wrap catches the eye of passers-by and is extremely noticeable! It’s also great for branding because it’s so transparent.

Proper Areas to Store Food in the Refrigerator

1. Top and Middle Shelves

The top and middle shelf are perfect for ready-to-eat foods like dairy products, ready meals and packaged foods, leftovers, cooked meats, and prepared salads.

To avoid infection, keep everything covered with Thong Guan Klarity plastic wrap or in sealed containers.

Ready-to-eat foods are kept on the top shelf of the refrigerator, away from raw foods, to prevent dangerous bacteria from spreading from raw to cooked meals.

2. Bottom Shelf

To prevent raw meat, poultry, and fish from contacting or leaking onto other items, place them in sealed containers or plastic wrap.

To avoid cross-contamination, raw meats should always be kept at the bottom of the fridge.

Make sure each item is wrapped or in a sealed container to avoid cross-contamination with other foods.

3. Salad and Fruit Drawer

The salad drawer is perfect for fruits, vegetables, and salads that have been washed and dried before being stored. To keep your fruit, veggies, and salad safe from contamination, wrap them in paper or plastic with air holes.

To prevent salads and herbs from drying out and to keep them fresher for longer, you can wrap them in a wet paper towel before storing them.

Here’s What to Do to Make Your Food Last Longer in the Refrigerator

- Check to see if your refrigerator is keeping items cold enough. Set your refrigerator to 4 degrees Celsius or below. If you’re not sure, get a fridge thermometer to make sure everything is in top condition.

- Make sure your refrigerator isn’t overloaded. This will generate heated pockets, which may cause food to spoil more quickly.

Use the additional humidity in the crisper drawers to your advantage. Keep leafy greens and other vegetables in the enclosure that will benefit from the excess moisture that accumulates. Set the drawer’s dial to the high-humidity setting and your fruits and vegetables will last longer. - Food packaging should not be reused. Transfer your food especially proteinous foods to a fresh, dry airtight container or plastic food wrap once opened.

- Familiarize yourself with the recommended period for keeping food, including condiments, in your refrigerator. Some foods have a shorter shelf life than you would expect.

Tip: To keep track of when you opened the jars, use a roll of tape and a permanent marker to date them. This will serve as a reminder to consume them so they don’t go stale before their time.

In a Nutshell

Thong Guan plastic food wrap isn’t just for covering food bowls. Plastic wrap can be used in a variety of ways. Fruits, such as bananas, can be wrapped to keep them fresh.

To store herbs and leafy vegetables like lettuce in the fridge, wrap them in plastic wrap. If you are making sandwiches but don’t want to keep them in a container, plastic wrap is great for storing sandwiches.

You can also prevent bottle leaking by covering the mouth of the bottle with plastic wrap before placing the cap. Fruits like cherries, berries, and grapes can also be wrapped to avoid freezer burn.

It will keep the food fresh for a longer period. Wrapping your meals and keeping them at a temperature below 40 degrees Fahrenheit will help your food stay safer for extended periods by inhibiting the growth of bacteria.

5 Plastic Alternatives When Running into Resin Shortages

The COVID-19 pandemic has massively disrupted the global supply chain. As a result, more and more organizations are looking for reliable and efficient alternatives to plastics to overcome resin shortages.

As many companies are suffering from material shortages, it causes price fluctuations and adversely affects the production of plastic-based components.

The good news is that there has been a lot of innovation in material development processes, and more manufacturers are exploring alternatives to resins.

Whenever an industry faces challenges like material shortages, they have the opportunity to explore more options and optimize processes with the help of modern tools and technology.

Nowadays, many alternatives are available; they act as a reliable replacement for common plastics like polycarbonate.

Different types of plastic wraps and stretch wraps are now available that allow consumers and large-scale organizations to overcome shortages and continue with their business processes.

Following are the top 5 plastic alternatives to resin shortages:

1. Polysulfone (PSU)

This resin is a crystalline, translucent, pale-amber high-performance thermoplastic with reliable melting stability.

As a result, it is capable of being processed with the help of standard thermoplastic processing methods. PSU is a highly popular component often used in various types of plastic wrap.

PSU also has good chemical and hydrolytic stability, as well as exceptional mechanical, electrical, and thermophysical characteristics.

The resin’s properties combine to make it ideal for components such as plumbing components, sterilizable plastic parts for medical equipment, and membranes for water treatment, gas separation, and other applications.

2. Polyphthalmide (PPA)

Semi-aromatic polyamides, such as PPA, are frequently a less costly alternative to fully aromatic aramids. PPA has a mixture of aromatic and aliphatic groups.

It significantly decreases moisture absorption that leads to less dimensional changes and more stable characteristics.

The material is ideal for goods that must be exposed to harsher chemicals and temperatures over extended periods of time.

Motor components, coolant pumps, bearing pads, resonators, and other items are examples of typical uses.

3. Polyphenylene sulfide (PPS)

PPS has a high melting point and low solubility, that that’s why it requires specific processing to make components out of it.

However, its aromatic ring structure gives it excellent heat and chemical resistance, good dimensional stability, and high tensile and structural strength.

PPS is a commonly utilized polyphenylene because of its flame-retardant characteristics and excellent electrical properties.

Electrical and electronic parts, as well as mechanical parts in vehicles and precision engineering, are common applications of PPS.

4. Polyphenylene oxide (PPO)

PPO has good tensile and impact strength and is resistant to a variety of chemicals, including steam and water.

However, it is susceptible to stress cracking, and that’s why it has limited applications. PPO has a problem with melt processing because it requires a high glass-transition temperature.

As a result, it’s frequently mixed with high-impact polystyrene (HIPS) for use in pump components, fan impellors, catalyst supports, and other applications in the automotive and electronics industries.

Moreover, it is also used in high-quality plastic wraps by large-scale organizations.

5. Syndiotactic polystyrene (SPS)

The plastic alternative, known as Xarec, is the first syndiotactic polystyrene (SPS) resin. The unique structure provides for a wide range of desirable features.

SPS is heat resistant, hydrolysis resistant, and chemically resistant to corrosion by different acids and alkalis, including vehicle oil and antifreeze. It also has a low specific gravity, which reduces part weight and cost.

SPS is a suitable material for electrical components in a variety of hybrid electric cars, as well as an important component in common household products. It’s also seen to be a good choice for the environment.

The Eco-friendliness of SPS is a major reason why it is becoming highly popular among customers as well as stretch wrap manufacturers.

The Bottom Line

Plant-based plastics, or bioplastics, are becoming very popular because they are biodegradable and do not reduce the quality of stretch wraps.

Now is the best time for companies and plastic wrap manufacturers to explore alternatives like the ones discussed above and implement the best solutions to overcome shortages.

There is no doubt that current shortages are causing great issues in the global supply. Plastic wraps are needed in every industry.

With things going back to some semblance of normalcy, these shortages will be overcome, and industries will continue operating with better and more efficient packaging options.